Cable Cross-Section Calculation: Innovative Techniques Unveiled

Understanding Cable Cross-Section Calculation

Importance of Cable Cross-Section

The cable cross-section might seem like a mundane detail in electrical engineering, but its significance cannot be overstated. Imagine this: you’re setting up a new electrical circuit for your home theater system, and you’ve carefully selected all the components. But if you neglect to consider the cross-section of the cables carrying power to your speakers and amplifiers, you could end up with a system that underperforms or even poses a safety hazard.

Contents

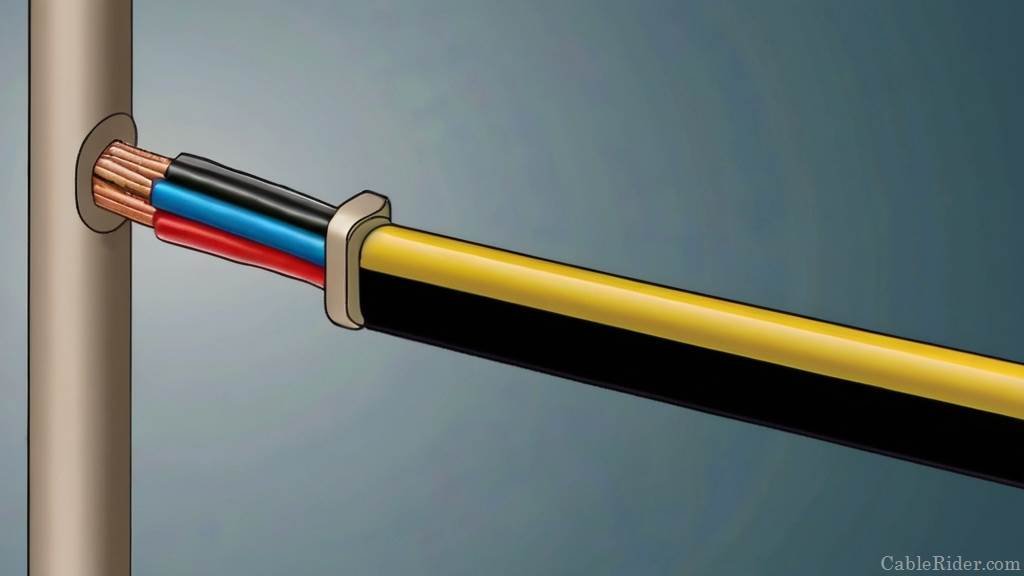

ToggleThe cross-section of a cable directly impacts its ability to conduct electrical current efficiently. Too small a cross-section can lead to excessive voltage drop, overheating, and potential damage to connected devices. On the flip side, oversized cables waste resources and can be unnecessarily bulky and expensive.

Factors Influencing Cable Cross-Section Calculation

Voltage Drop Considerations

Voltage drop refers to the decrease in voltage along the length of a cable due to its inherent resistance. This phenomenon becomes more pronounced as the length of the cable increases or the current flowing through it grows. Excessive voltage drop can result in devices receiving insufficient power, leading to poor performance or even malfunction.

Calculating the appropriate cable cross-section involves balancing the desired voltage drop with practical considerations such as cost and available space. Engineers use mathematical formulas and specialized software to optimize cable sizes for specific applications, ensuring that voltage drop remains within acceptable limits.

Current Carrying Capacity

The cross-section of a cable also affects its current carrying capacity, or the maximum amount of electrical current it can safely conduct without overheating. This capacity depends on factors such as the material composition of the conductor, ambient temperature, and insulation type.

When sizing cables for a given load, engineers must consider not only the magnitude of the current but also its duration and whether it is continuous or intermittent. Failure to account for these factors can lead to overheating, insulation degradation, and ultimately, electrical fires.

Environmental Conditions

Environmental factors play a crucial role in cable cross-section calculation. Cables installed outdoors or in harsh industrial environments may be exposed to temperature extremes, moisture, chemical exposure, and mechanical stress. These conditions can affect cable performance and lifespan, necessitating careful selection of materials and design parameters.

For example, cables used in marine applications must be resistant to corrosion from saltwater, while those installed in underground conduits must withstand pressure from surrounding soil. Engineers must factor in these environmental considerations when determining the appropriate cable cross-section to ensure long-term reliability and safety.

In summary, cable cross-section calculation is a critical aspect of electrical design that requires careful consideration of voltage drop, current carrying capacity, and environmental factors. By understanding these principles and employing appropriate calculation methods, engineers can ensure the optimal performance and safety of electrical systems in a wide range of applications.

Fundamental Concepts of Cable Cross-Section Calculation

Ohm’s Law and its Application

Ohm’s Law is the cornerstone of electrical engineering, providing a fundamental relationship between voltage, current, and resistance. By understanding this principle, engineers can accurately calculate cable cross-sections to ensure optimal performance and safety in electrical systems.

Relationship between Voltage, Current, and Resistance

Ohm’s Law states that the current flowing through a conductor is directly proportional to the voltage applied across it and inversely proportional to the resistance of the conductor. In mathematical terms, it can be expressed as:

V=I×RV = I times RV=I×R

Where:

- VVV is the voltage (in volts)

- III is the current (in amperes)

- RRR is the resistance (in ohms)

This equation illustrates the intimate relationship between voltage, current, and resistance. For example, if the voltage remains constant and the resistance increases, the current will decrease proportionally. Conversely, if the resistance remains constant and the voltage increases, the current will increase accordingly.

Implications for Cable Sizing

The application of Ohm’s Law in cable sizing is straightforward yet crucial. By understanding the relationship between voltage, current, and resistance, engineers can determine the appropriate cross-section of a cable to ensure that it can safely carry the required current without excessive voltage drop or overheating.

When sizing cables, engineers typically consider the maximum current expected to flow through the circuit and the length of the cable run. By calculating the voltage drop and selecting a cable with a suitable cross-section, they can minimize energy losses and ensure the efficient operation of electrical devices.

Specific Resistance and Conductivity

In addition to Ohm’s Law, the concepts of specific resistance and conductivity play a significant role in cable cross-section calculation. These properties are inherent to the material composition of the conductor and influence its ability to conduct electrical current efficiently.

Impact on Cable Cross-Section

Specific resistance, also known as resistivity, quantifies the inherent resistance of a material to the flow of electrical current. Materials with lower resistivity exhibit higher conductivity and are therefore more efficient conductors of electricity.

When selecting materials for cables, engineers prioritize those with low specific resistance to minimize energy losses and optimize system performance. Copper, for example, is prized for its high conductivity and low resistivity, making it a popular choice for electrical wiring in residential, commercial, and industrial applications.

Selection of Suitable Materials

The selection of materials for cables involves a careful balance of electrical, mechanical, and environmental factors. Engineers must consider not only the conductivity and resistivity of the material but also its durability, flexibility, and resistance to corrosion and temperature extremes.

In addition to copper, other materials such as aluminum and various alloys may be used in cable manufacturing to meet specific requirements. Each material has its advantages and limitations, and the selection process involves evaluating trade-offs to ensure the optimal performance and longevity of the cable.

In conclusion, the fundamental concepts of Ohm’s Law, specific resistance, and conductivity are essential for understanding cable cross-section calculation. By applying these principles and considering factors such as voltage drop, current carrying capacity, and environmental conditions, engineers can design electrical systems that are safe, efficient, and reliable.

Methods for Cable Cross-Section Calculation

3.1 Power-Based Calculation

Power-based calculation is a fundamental approach used by engineers to determine the appropriate cross-section of a cable based on the power requirements of the electrical system.

Understanding Power Requirements

Before diving into cable sizing, it’s essential to have a clear understanding of the power requirements of the system. This involves identifying the total power consumption of connected devices, as well as any additional factors such as starting currents or power factor correction.

For example, if you’re designing a circuit for a home entertainment center, you’ll need to consider the power ratings of the TV, speakers, amplifiers, and other components. By summing up the power requirements of each device, you can determine the total power demand of the system.

Formula for Power-Based Cross-Section Calculation

Once the power requirements are known, engineers can use a simple formula to calculate the cross-section of the cable needed to safely carry that power without excessive voltage drop. The formula is based on Ohm’s Law and takes into account the voltage drop and current carrying capacity of the cable.

S=P×L×KVS = frac{P times L times K}{V}S=VP×L×K

Where:

- SSS is the cross-section of the cable (in square millimeters)

- PPP is the total power consumption (in watts)

- LLL is the length of the cable run (in meters)

- KKK is a correction factor based on the type of installation and environmental conditions

- VVV is the allowable voltage drop (in volts)

By plugging in the values for power, cable length, and voltage drop, engineers can quickly calculate the required cross-section of the cable to meet the system’s power demands.

3.2 Current-Based Calculation

Another common method for cable cross-section calculation is based on the maximum current carrying capacity of the cable.

Determining Current Load

Before applying the current-based formula, engineers must accurately determine the maximum current load expected to flow through the cable under normal operating conditions. This involves considering factors such as the power ratings of connected devices, starting currents, and safety margins.

For instance, if you’re designing a circuit for a workshop with multiple power tools, you’ll need to account for the combined current draw of all the tools when they’re operating simultaneously. Failure to accurately assess the current load can lead to undersized cables and potential safety hazards.

Application of Current-Based Formula

Once the current load is determined, engineers can use a formula based on Ohm’s Law to calculate the cross-section of the cable required to safely carry that current without overheating.

S=I×L×KΔVS = frac{I times L times K}{Delta V}S=ΔVI×L×K

Where:

- SSS is the cross-section of the cable (in square millimeters)

- III is the maximum current load (in amperes)

- LLL is the length of the cable run (in meters)

- KKK is a correction factor based on the type of installation and environmental conditions

- ΔVDelta VΔV is the allowable voltage drop (in volts)

By inputting the values for current load, cable length, and voltage drop, engineers can determine the minimum cross-section of the cable needed to safely conduct the required current without exceeding temperature limits.

In conclusion, power-based and current-based calculation methods provide engineers with practical tools for sizing cables to meet the power demands of electrical systems. By understanding these methods and their underlying principles, engineers can ensure the safe and efficient operation of electrical installations in various applications.

Cable Load and Length Calculation

4.1 Load Analysis for Cable Sizing

When it comes to cable sizing, load analysis is the cornerstone of the process. Understanding the characteristics of the load and accounting for variations are essential steps in ensuring that the selected cable can meet the demands of the electrical system.

Identifying Load Characteristics

The first step in load analysis is to identify the characteristics of the load that the cable will be supplying power to. This includes factors such as the type of equipment or appliances connected to the circuit, their power ratings, and their operating conditions.

For example, if you’re designing a circuit for a commercial kitchen, you’ll need to consider the power requirements of appliances such as ovens, refrigerators, and food processors. Each appliance may have different power ratings and usage patterns, which must be taken into account when sizing the cable.

Accounting for Variations in Load

In real-world applications, electrical loads are rarely constant. They fluctuate based on factors such as usage patterns, environmental conditions, and the number of devices connected to the circuit. As such, it’s crucial to account for these variations when sizing the cable.

Engineers typically apply safety factors or derating factors to account for uncertainties in load conditions. These factors ensure that the selected cable can safely handle peak loads and transient surges without exceeding its rated capacity.

For instance, in a residential setting, engineers may apply a safety factor to account for the possibility of additional appliances being added to the circuit in the future. By doing so, they can ensure that the cable has sufficient capacity to accommodate potential changes in load.

4.2 Length Considerations

In addition to load analysis, cable length is another critical factor that influences cable sizing. The length of the cable run directly impacts its resistance and voltage drop, which in turn affect the cross-section of the cable required for optimal performance.

Impact of Cable Length on Cross-Section

As the length of the cable increases, so does its resistance. This results in higher voltage drop along the length of the cable, which can adversely affect the performance of the electrical system. To mitigate this voltage drop, engineers may need to increase the cross-section of the cable to compensate for the longer length.

For example, in a large industrial facility with extensive cable runs, engineers must carefully consider the length of each cable when selecting sizes. Failure to account for cable length can result in excessive voltage drop, decreased efficiency, and potential damage to equipment.

Practical Approaches for Length Calculation

Calculating the exact length of cable required for a given installation can be challenging, especially in complex systems with multiple branches and connections. However, engineers can use practical approaches such as route mapping, cable routing software, and on-site measurements to estimate cable lengths accurately.

By taking into account factors such as cable routing paths, bends, and obstacles, engineers can minimize excess cable length and reduce material costs. Additionally, regular maintenance and inspection of cables can help identify any issues such as damage or degradation that may affect their performance over time.

In conclusion, cable load and length calculation are essential aspects of cable sizing that require careful analysis and consideration of various factors. By understanding load characteristics, accounting for load variations, and evaluating cable length, engineers can select the appropriate cable size to ensure the safe and efficient operation of electrical systems.

Cable Cross-Section Calculation Techniques

5.1 Manual Calculation Methods

Manual calculation methods are the traditional approach used by engineers to determine the cross-section of a cable. While they require a solid understanding of electrical principles and mathematical formulas, they offer flexibility and control over the calculation process.

Hand Calculations Using Formulas

One common manual calculation method involves using mathematical formulas based on fundamental electrical principles such as Ohm’s Law and the power equation. Engineers input parameters such as voltage drop, current load, and cable length into these formulas to calculate the required cross-section of the cable.

For example, engineers can use the formula S=I×L×KΔVS = frac{I times L times K}{Delta V}S=ΔVI×L×K to calculate the cross-section (SSS) of the cable based on the maximum current load (III), cable length (LLL), correction factor (KKK), and allowable voltage drop (ΔVDelta VΔV).

Considerations for Accuracy

While manual calculation methods offer precision and control, they also require careful attention to detail to ensure accuracy. Engineers must account for factors such as temperature, insulation type, and ambient conditions, which can affect the performance of the cable.

Additionally, manual calculations are prone to human error, especially when dealing with complex systems or multiple variables. Engineers must double-check their calculations and validate the results to ensure that they meet the requirements of the electrical system.

5.2 Software-Assisted Calculation

With the advent of technology, software-assisted calculation methods have become increasingly popular among engineers for cable cross-section calculation. These tools offer automation, advanced algorithms, and graphical interfaces to streamline the calculation process and improve accuracy.

Overview of Available Tools

There is a wide range of software tools available for cable cross-section calculation, ranging from basic calculators to sophisticated simulation software. These tools typically allow engineers to input parameters such as load characteristics, cable length, and environmental conditions, and then generate detailed reports and recommendations based on mathematical models and standards.

For example, popular software packages such as ETAP, CYMCAP, and SKM PowerTools offer comprehensive features for cable sizing, voltage drop analysis, and thermal modeling. These tools leverage advanced algorithms and databases to provide accurate and efficient solutions for complex electrical systems.

Advantages and Limitations

Software-assisted calculation methods offer several advantages over manual methods, including speed, accuracy, and scalability. With software tools, engineers can quickly analyze multiple scenarios, perform sensitivity analysis, and generate detailed reports for documentation and compliance purposes.

However, software tools also have limitations, including cost, learning curve, and reliance on input data quality. Engineers must invest time and resources in training and familiarizing themselves with the software interface and functionality. Additionally, software tools may require periodic updates and maintenance to ensure compatibility with evolving standards and regulations.

In conclusion, both manual calculation methods and software-assisted tools have their place in cable cross-section calculation. Engineers should consider factors such as complexity, accuracy requirements, and available resources when selecting the appropriate method for their specific application.

Real-World Applications and Examples

6.1 Residential Wiring Scenarios

Residential wiring scenarios present unique challenges and considerations for cable cross-section calculation. From powering household appliances to ensuring the safety of occupants, engineers must carefully analyze various factors to design efficient and reliable electrical systems.

Determining Cross-Section for Household Circuits

When wiring a residential property, engineers must determine the appropriate cross-section of cables to meet the power demands of household circuits. This involves considering factors such as the number and types of appliances connected to each circuit, as well as the length of cable runs.

For example, in a kitchen circuit that powers multiple appliances such as a refrigerator, microwave, and dishwasher, engineers must calculate the total power consumption and select cables with adequate cross-sections to handle the load without excessive voltage drop.

Safety Considerations

Safety is paramount in residential wiring scenarios, and engineers must ensure that the selected cables meet regulatory standards and minimize the risk of electrical hazards. This includes considering factors such as insulation type, temperature ratings, and overload protection mechanisms.

For instance, engineers may choose cables with fire-resistant insulation for circuits that power high-power appliances such as electric stoves or space heaters. Additionally, they must implement proper grounding and bonding practices to prevent electric shock and ensure the safety of occupants.

6.2 Industrial and Commercial Installations

Industrial and commercial installations pose unique challenges for cable cross-section calculation due to the diverse range of equipment and machinery involved, as well as stringent regulatory requirements.

Sizing Cables for Heavy Machinery

In industrial settings such as manufacturing plants or warehouses, engineers must size cables to power heavy machinery and equipment efficiently. This involves considering factors such as motor starting currents, voltage drop, and environmental conditions.

For example, when sizing cables for a conveyor belt system in a factory, engineers must account for the high starting currents required to overcome inertia and friction during startup. By selecting cables with sufficient cross-sections and derating factors, they can ensure the reliable operation of the machinery.

Compliance with Regulatory Standards

Compliance with regulatory standards is essential in industrial and commercial installations to ensure the safety of workers and the integrity of electrical systems. Engineers must adhere to codes and standards such as the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) guidelines.

For instance, in hazardous environments such as chemical plants or oil refineries, engineers must select cables with appropriate ratings for flammability, chemical resistance, and explosion-proof construction. Failure to comply with these standards can result in serious consequences, including equipment damage, injuries, and regulatory fines.

In summary, cable cross-section calculation plays a critical role in residential, industrial, and commercial installations, ensuring the safe and efficient operation of electrical systems. By considering factors such as load requirements, safety considerations, and regulatory compliance, engineers can design electrical systems that meet the needs of various applications while minimizing risks and maximizing performance.

Future Trends and Innovations in Cable Cross-Section Calculation

7.1 Automation and Machine Learning Integration

The integration of automation and machine learning technologies holds immense potential for revolutionizing cable cross-section calculation processes. By leveraging advanced algorithms and data analytics, engineers can enhance the accuracy and efficiency of cable sizing in various applications.

Potential for Enhanced Accuracy and Efficiency

Automation and machine learning algorithms can analyze vast amounts of data and identify patterns that may not be apparent to human engineers. This capability allows for more accurate predictions of load requirements, voltage drop, and cable sizing, leading to optimized designs and reduced margins of error.

For example, machine learning algorithms can analyze historical data on electrical loads, environmental conditions, and cable performance to predict future load patterns and recommend optimal cable sizes. This proactive approach enables engineers to anticipate potential issues and design more resilient and efficient electrical systems.

Challenges and Opportunities in Implementation

While automation and machine learning offer significant benefits, their implementation in cable cross-section calculation presents several challenges. Engineers must ensure the accuracy and reliability of algorithms, validate results against real-world data, and address issues such as model bias and overfitting.

Additionally, the adoption of automation and machine learning technologies may require investments in infrastructure, training, and data management systems. However, the long-term benefits, including improved efficiency, reduced costs, and enhanced design capabilities, outweigh these initial challenges.

7.2 Sustainable Materials and Design Practices

As the world increasingly focuses on sustainability and environmental stewardship, there is a growing demand for eco-friendly solutions in cable manufacturing and design. Sustainable materials and design practices offer opportunities to reduce the environmental impact of electrical systems while improving performance and efficiency.

Eco-Friendly Solutions for Cable Manufacturing

Manufacturers are exploring alternative materials and manufacturing processes to reduce the environmental footprint of cables. This includes using recycled materials, bio-based polymers, and renewable energy sources in cable production.

For instance, some companies are developing cables with insulation materials derived from plant-based sources such as corn or sugarcane. These eco-friendly materials offer comparable performance to traditional materials while significantly reducing carbon emissions and resource consumption.

Implications for Cross-Section Calculation and Design

The adoption of sustainable materials and design practices in cable manufacturing has implications for cross-section calculation and design. Engineers must consider the unique properties and characteristics of eco-friendly materials when sizing cables and assessing their performance.

For example, sustainable materials may have different thermal conductivity, insulation resistance, or mechanical properties compared to traditional materials. Engineers must account for these factors in their calculations to ensure the safety, reliability, and longevity of the electrical system.

In summary, automation, machine learning, and sustainable materials offer exciting opportunities for innovation in cable cross-section calculation. By embracing these trends and incorporating them into their design processes, engineers can develop more efficient, resilient, and environmentally friendly electrical systems for the future.