Electric Wires: Innovations & Smart Solutions

Understanding Electric Wires and Cables

The Basics of Electric Wires

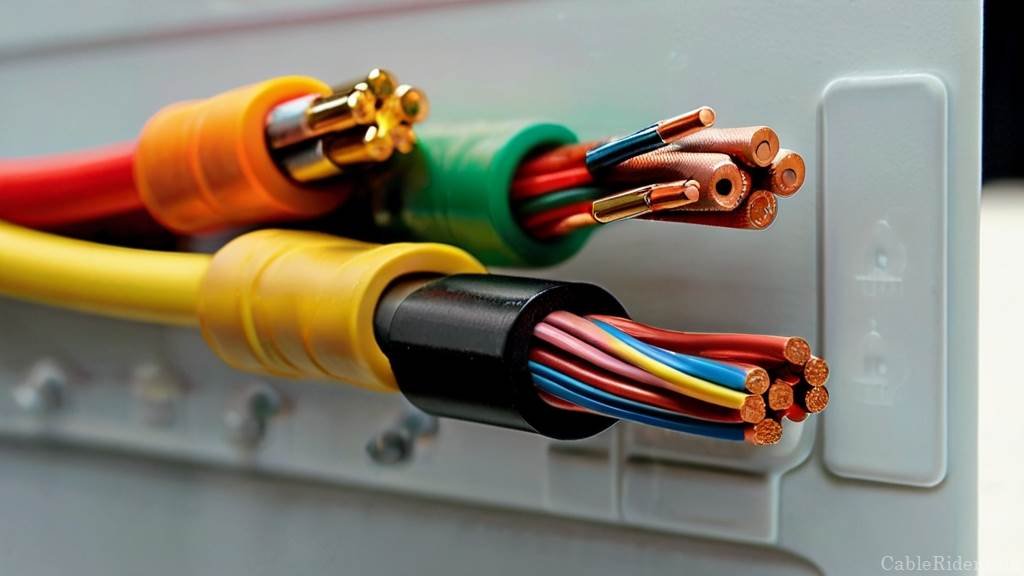

Electric wires are the unsung heroes of our modern world, silently carrying electricity to power our homes, businesses, and gadgets. But what exactly are they? At their core, electric wires are conductive materials, typically copper or aluminum, encased in insulation. This insulation serves a crucial role, preventing the wires from short-circuiting or causing fires by keeping the electricity confined to its intended path.

Contents

ToggleBut how does electricity flow through these wires? It’s all about electrons, those tiny particles that orbit the nucleus of an atom. When an electric current is applied, electrons move from atom to atom along the wire, creating the flow of electricity. It’s like a relay race, with each electron passing the baton to the next in line.

Exploring Cable Types for Home Usage

When it comes to wiring your home, not all cables are created equal. There’s a dizzying array of options to choose from, each suited for different applications and environments. Let’s break down some of the most common types:

-

Non-Metallic (NM) Cable: Also known as Romex, NM cable is the go-to choice for most residential wiring projects. It consists of two or more insulated conductors bundled together with a bare ground wire, all encased in a plastic sheath. NM cable is easy to work with and suitable for indoor use.

-

Armored Cable (AC): For added protection in areas where wiring might be exposed to damage, armored cable is the way to go. It features a flexible metal sheath surrounding the insulated conductors, providing a barrier against physical harm.

-

Twisted Pair Cable: Commonly used for telephone and networking applications, twisted pair cable consists of two insulated copper wires twisted together. This design helps reduce electromagnetic interference, ensuring clear communication signals.

-

Coaxial Cable: If you’ve ever hooked up a cable TV or internet connection, you’re familiar with coaxial cable. It features a central conductor surrounded by insulation, a metallic shield, and an outer insulating layer. Coaxial cable is prized for its ability to carry high-frequency signals with minimal interference.

-

Underground Feeder (UF) Cable: As the name suggests, UF cable is designed for buried applications, such as outdoor lighting or underground wiring. It’s similar to NM cable but with added protection against moisture and soil corrosion.

-

Low Voltage Wiring: Used for applications like doorbell systems and thermostat controls, low voltage wiring typically consists of small-gauge conductors encased in a protective jacket. Despite their diminutive size, these wires play a crucial role in powering essential household functions.

With so many options available, it’s essential to choose the right cable for the job to ensure safety and efficiency in your electrical installations. Whether you’re wiring a new home or tackling a DIY project, understanding the different types of cables at your disposal is key to success.

So, what’s the best cable for your home wiring needs? Well, that depends on factors like the intended use, environmental conditions, and local building codes. It’s always a good idea to consult with a qualified electrician to ensure you’re selecting the right cable for your specific application. After all, when it comes to electrical wiring, safety always comes first!

Different Types of Power Cables

Overview of Power Cable Varieties

When it comes to powering our homes, offices, and industries, power cables are the unsung heroes working tirelessly behind the scenes. These cables come in a variety of shapes, sizes, and materials, each designed to meet specific needs and requirements. Let’s dive into the diverse world of power cables and explore the different varieties available.

1. Single-Core Cables:

- Single-core cables consist of a single conductor surrounded by insulation and an outer sheath. They’re commonly used in applications where flexibility and ease of installation are paramount, such as household wiring and small-scale electrical projects.

2. Multi-Core Cables:

- Multi-core cables feature multiple conductors bundled together within a single sheath. These cables are ideal for applications requiring the transmission of multiple signals or power feeds, such as industrial machinery and complex electrical systems.

3. Armored Cables:

- Armored cables are reinforced with a layer of metal, typically steel or aluminum, to provide added protection against physical damage and environmental hazards. They’re commonly used in outdoor installations, underground wiring, and areas prone to mechanical stress.

4. Submarine Cables:

- Submarine cables are specifically designed for underwater use, such as connecting offshore wind farms to the mainland power grid or interconnecting islands. These cables are engineered to withstand the harsh conditions of the ocean, including saltwater corrosion and pressure variations.

5. High-Voltage Cables:

- High-voltage cables are built to handle extremely high electrical voltages, typically ranging from thousands to millions of volts. These cables play a crucial role in transmitting electricity over long distances, such as between power plants and substations, with minimal loss.

6. Low-Voltage Cables:

- Low-voltage cables are designed for applications requiring lower electrical voltages, typically up to 1000 volts. They’re commonly used in residential and commercial buildings to power lighting, appliances, and other electrical devices.

Understanding Insulation Materials

The insulation surrounding power cables is not just for show – it serves a critical role in ensuring the safety and reliability of electrical installations. Different insulation materials offer varying levels of protection against electrical hazards, environmental factors, and mechanical stress. Let’s take a closer look at some common insulation materials used in power cables:

-

Polyvinyl Chloride (PVC): PVC is one of the most widely used insulation materials due to its affordability, flexibility, and resistance to moisture and chemicals. It’s commonly found in low-voltage cables for indoor applications.

-

Cross-Linked Polyethylene (XLPE): XLPE insulation offers excellent thermal and electrical properties, making it ideal for high-voltage and underground cables. It’s known for its durability, resistance to heat and abrasion, and low dielectric loss.

-

Ethylene Propylene Rubber (EPR): EPR insulation is prized for its flexibility, resistance to environmental factors, and high dielectric strength. It’s often used in medium-voltage cables for outdoor and industrial applications.

-

Silicone Rubber: Silicone rubber insulation excels in extreme temperature environments, withstanding both high and low temperatures without sacrificing performance. It’s commonly found in specialty cables for aerospace, automotive, and medical applications.

Comparing Conductors: Copper vs. Aluminum

When it comes to choosing the conductor material for power cables, copper and aluminum are the top contenders. Each material has its own set of advantages and disadvantages, making them suitable for different applications. Let’s compare the two:

Copper Conductors:

- Advantages:

- Excellent electrical conductivity

- High tensile strength

- Resistant to corrosion

- Disadvantages:

- More expensive than aluminum

- Heavier and less flexible

- Prone to theft due to scrap value

Aluminum Conductors:

- Advantages:

- Lightweight and flexible

- Less expensive than copper

- Suitable for long-distance transmission

- Disadvantages:

- Lower conductivity than copper

- More prone to oxidation and corrosion

- Requires larger cross-sectional area for equivalent conductivity

In conclusion, the choice between copper and aluminum conductors depends on factors such as cost, conductivity requirements, environmental conditions, and installation constraints. By understanding the characteristics of each material, you can make an informed decision to ensure optimal performance and longevity of your power cables.

Essential Wires for Internal Wiring

Role of Electrical Wires in Internal Wiring

Ever wondered what makes your home’s lights flicker on and appliances hum to life? Look no further than the humble electrical wires snaking through your walls and ceilings. These unsung heroes play a vital role in powering our modern lives, serving as conduits for the flow of electricity from the main power source to our lights, outlets, and devices.

But their importance goes beyond mere transportation of electrical current. Electrical wires also act as guardians of safety, ensuring that electricity flows only where it’s supposed to and preventing potentially dangerous short circuits or electrical fires. With the right wires in place, you can rest easy knowing that your home’s electrical system is up to code and operating safely.

So, what exactly makes a wire essential for internal wiring? It all boils down to a few key characteristics:

-

Conductivity: Essential wires must be made of highly conductive materials, such as copper or aluminum, to efficiently carry electricity from point A to point B without excessive resistance or energy loss.

-

Insulation: To prevent electrical shocks and fires, internal wiring must be insulated with materials that can withstand the rigors of everyday use and protect against exposure to moisture, heat, and physical damage.

-

Gauge: The size, or gauge, of a wire determines its current-carrying capacity and suitability for different applications. Essential wires for internal wiring must be appropriately sized to handle the expected electrical load without overheating or melting.

-

Compliance: Lastly, essential wires must meet industry standards and building codes to ensure they’re safe and reliable for use in residential and commercial buildings. Compliance with regulations helps protect both occupants and property from electrical hazards.

In summary, the role of electrical wires in internal wiring is to safely and efficiently deliver electricity to power our homes while protecting against potential hazards. Without these essential wires, our modern conveniences would grind to a halt, leaving us in the dark – both literally and figuratively.

Laying Out Wiring Schemes for Homes

Planning to wire up your new home or tackle a renovation project? Properly laying out wiring schemes is essential to ensure your electrical system functions smoothly and safely. Here’s a step-by-step guide to help you get started:

-

Assess Your Needs: Begin by determining your electrical requirements, including the number and placement of outlets, switches, and lighting fixtures. Consider factors such as room layout, furniture placement, and anticipated usage to create a comprehensive wiring plan.

-

Create a Floor Plan: Sketch out a floor plan of your home, marking the locations of existing electrical fixtures and appliances. Use this as a reference point to map out the placement of new wiring and outlets, taking care to avoid potential obstructions or hazards.

-

Design the Circuit Layout: Divide your home into separate electrical circuits, each serving a specific area or set of appliances. Plan circuits to minimize electrical load and prevent overloading, and ensure each circuit has its own dedicated breaker in the electrical panel.

-

Choose the Right Wiring: Select the appropriate type and gauge of wiring for each circuit based on its intended use and electrical requirements. Consult with a qualified electrician to ensure compliance with local building codes and regulations.

-

Map Out Wiring Routes: Plan the routing of electrical wires through walls, ceilings, and floors, taking care to avoid interference with structural elements or other utilities. Use conduits or cable trays where necessary to protect and organize wiring runs.

-

Label and Document: Clearly label electrical outlets, switches, and breaker panels to facilitate future maintenance and troubleshooting. Keep detailed documentation of your wiring layout, including circuit diagrams and wire color codes, for reference.

By following these steps and consulting with a professional electrician as needed, you can create a well-designed wiring scheme that meets your household’s needs and ensures a safe and efficient electrical system for years to come. With careful planning and attention to detail, you’ll be powering up your home with confidence in no time!

Cable Wiring: Installation and Techniques

Installation Guidelines for Safe Cable Wiring

Thinking of tackling a cable wiring project in your home? Before you dive in, it’s crucial to understand the importance of safe installation practices. Follow these guidelines to ensure your wiring project goes off without a hitch:

-

Plan Ahead: Start by mapping out the layout of your wiring project, considering factors such as the location of outlets, switches, and appliances. Plan routes that minimize exposure to potential hazards and avoid running cables through areas prone to moisture or heat.

-

Use the Right Materials: Select cables and wiring accessories that are suitable for the intended application and environment. Choose cables with the appropriate gauge and insulation rating for the electrical load and ensure all materials comply with relevant safety standards.

-

Turn Off Power: Before starting any work, always turn off the power to the area where you’ll be installing cables. Use a voltage tester to verify that the circuit is de-energized before proceeding, and never work on live electrical circuits to avoid the risk of electric shock.

-

Follow Code Requirements: Familiarize yourself with local building codes and regulations governing electrical installations in your area. Ensure your wiring project meets all applicable requirements for safety, performance, and compliance.

-

Maintain Clearance: Leave adequate clearance around electrical panels, junction boxes, and other components to allow for safe access and maintenance. Avoid overcrowding wiring runs and maintain proper spacing between cables to prevent overheating and interference.

-

Secure Cables Properly: Use appropriate fasteners, such as cable staples or clamps, to secure cables to structural elements and prevent sagging or strain. Avoid over-tightening fasteners, which can damage the insulation and compromise safety.

-

Inspect and Test: Once the wiring is installed, conduct a thorough inspection to check for any signs of damage, improper connections, or code violations. Test circuits using a multimeter or continuity tester to ensure proper functionality before restoring power.

By following these installation guidelines, you can ensure your cable wiring project is completed safely and up to code, providing reliable electrical power for years to come.

Techniques for Securing and Organizing Cable Wiring

Effective cable management is essential for maintaining a tidy and efficient electrical system. Whether you’re wiring a new home or organizing existing cables, these techniques can help you secure and organize your wiring with ease:

-

Cable Routing: Plan cable routes carefully to minimize clutter and ensure cables follow logical paths between connection points. Use cable trays, conduits, or raceways to organize and protect wiring runs, especially in areas with high foot traffic or exposure to hazards.

-

Bundle Cables: Group cables together using cable ties or Velcro straps to create neat and manageable bundles. Avoid over-tightening ties, which can damage the insulation or constrict airflow around the cables.

-

Labeling: Clearly label cables at both ends to identify their purpose and destination. Use color-coded labels or markers to distinguish between different types of cables or circuits, making it easy to trace and troubleshoot connections in the future.

-

Support and Strain Relief: Provide adequate support for cables to prevent sagging or strain, especially in vertical runs or overhead installations. Use cable hooks, brackets, or supports to secure cables at regular intervals and minimize stress on connections.

-

Segregation: Separate power cables from low-voltage or data cables to prevent electromagnetic interference and ensure optimal signal quality. Keep sensitive cables away from sources of electrical noise, such as motors or fluorescent lights, to minimize interference.

-

Accessibility: Maintain accessibility to wiring and connection points for future maintenance or upgrades. Avoid burying cables behind inaccessible walls or under heavy furniture, and leave slack in wiring runs to accommodate adjustments or repairs.

By implementing these techniques for securing and organizing cable wiring, you can create a clean and efficient electrical system that’s easy to maintain and troubleshoot. Whether you’re a seasoned electrician or a DIY enthusiast, proper cable management is essential for a safe and reliable wiring installation.

Safety Measures for Cable Installation

Importance of Safety Protocols in Cable Installation

When it comes to installing electrical cables, safety should always be the top priority. Electrical wiring projects can pose serious risks if not handled properly, including electric shock, fires, and even fatalities. That’s why following safety protocols is crucial to protect yourself, your loved ones, and your property. Here’s why safety measures are essential in cable installation:

-

Prevention of Accidents: Safety protocols help minimize the risk of accidents and injuries during cable installation. By following established guidelines and best practices, you can avoid common hazards such as electric shocks, falls, and cuts, ensuring a safer work environment for everyone involved.

-

Protection Against Electrical Hazards: Electrical cables carry powerful currents that can cause severe injuries or fatalities if mishandled. Safety measures such as wearing insulated gloves, using insulated tools, and de-energizing circuits before working on them help protect against electrical hazards and reduce the likelihood of accidents.

-

Mitigation of Fire Risks: Faulty wiring installations can lead to electrical fires, posing a significant threat to life and property. Adhering to safety protocols, such as using fire-resistant materials, maintaining proper clearance distances, and avoiding overloading circuits, can help mitigate the risk of fires and ensure a safer living or working environment.

-

Compliance with Regulations: Following safety protocols is not just a matter of common sense – it’s also a legal requirement. Electrical installations must comply with national and local building codes, as well as industry standards and regulations, to ensure they meet minimum safety requirements. Failure to adhere to these regulations can result in fines, penalties, and even legal liability in the event of accidents or injuries.

-

Peace of Mind: By prioritizing safety in cable installation, you can enjoy peace of mind knowing that your electrical system is installed correctly and safely. Whether you’re a professional electrician or a DIY enthusiast, taking the time to follow safety protocols ensures that you and your loved ones are protected from potential hazards.

Ensuring Compliance with Electrical Codes and Regulations

Electrical codes and regulations are in place to safeguard the public and ensure the safety and reliability of electrical installations. Compliance with these standards is essential to prevent accidents, protect property, and maintain the integrity of the electrical system. Here’s how to ensure compliance with electrical codes and regulations:

-

Stay Informed: Keep up-to-date with the latest electrical codes and regulations issued by relevant authorities, such as the National Electrical Code (NEC) in the United States or the International Electrotechnical Commission (IEC) standards internationally. Familiarize yourself with the requirements applicable to your jurisdiction and type of electrical installation.

-

Consult Experts: If you’re unsure about code requirements or the proper installation procedures, don’t hesitate to seek guidance from qualified electricians or electrical inspectors. These professionals have the knowledge and experience to ensure that your electrical installations meet regulatory standards and pass inspection.

-

Use Approved Materials: When selecting cables, wiring accessories, and other electrical components, always choose products that are tested and approved for use in your region. Look for certification labels or markings indicating compliance with relevant safety standards, such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association) certification.

-

Follow Installation Guidelines: Adhere to manufacturer instructions and industry best practices when installing electrical cables and equipment. Proper installation techniques, such as securely fastening cables, maintaining proper clearances, and using suitable connectors, are essential for ensuring compliance with electrical codes and regulations.

-

Schedule Inspections: Before commissioning a new electrical installation or making significant modifications to an existing system, schedule inspections by qualified electrical inspectors or regulatory authorities. These inspections help verify that the installation meets code requirements and is safe for use.

By ensuring compliance with electrical codes and regulations, you can protect yourself, your property, and others from potential hazards associated with electrical installations. Remember, safety always comes first when it comes to working with electricity, so take the necessary precautions to ensure a safe and reliable electrical system.

Troubleshooting Common Cable Issues

Identifying and Resolving Cable Wiring Problems

Cable wiring problems can be a real headache, causing frustration and inconvenience in our daily lives. From flickering lights to malfunctioning appliances, issues with electrical cables can disrupt our routines and pose safety hazards. Here’s how to identify and resolve common cable wiring problems:

-

Check for Loose Connections: Loose or corroded connections are a common cause of electrical issues. Start by inspecting electrical outlets, switches, and junction boxes for loose wires or signs of damage. Tighten any loose connections and replace damaged components as needed to restore proper functionality.

-

Inspect for Physical Damage: Examine cables for signs of physical damage, such as frayed insulation, exposed wires, or cuts. Damaged cables can pose safety risks and should be replaced immediately to prevent electrical hazards. Use electrical tape or heat shrink tubing to repair minor damage temporarily, but prioritize permanent replacement.

-

Test Circuit Continuity: Use a multimeter or continuity tester to check for continuity in electrical circuits. This helps identify open circuits, short circuits, or faulty components that may be causing issues. Trace the path of the wiring to locate the source of the problem and make necessary repairs or replacements.

-

Look for Overloaded Circuits: Overloaded circuits can cause circuit breakers to trip frequently or wires to overheat, leading to potential fire hazards. Identify and disconnect any appliances or devices that may be drawing excessive current from the circuit. Consider redistributing loads or adding additional circuits to alleviate the strain on existing wiring.

-

Inspect Grounding Systems: Proper grounding is essential for electrical safety and helps protect against electric shocks and equipment damage. Ensure that grounding wires are securely connected and that grounding systems are intact. Replace damaged or corroded grounding components to maintain effective grounding throughout the electrical system.

-

Consult a Professional: If you’re unable to identify or resolve cable wiring problems on your own, don’t hesitate to seek assistance from a qualified electrician. Professional electricians have the knowledge, experience, and specialized equipment needed to diagnose and repair complex electrical issues safely and efficiently.

By following these troubleshooting steps and taking proactive measures to address cable wiring problems, you can ensure a safe and reliable electrical system in your home or workplace.

Techniques for Repairing Damaged Cables

Dealing with damaged cables can be a frustrating experience, but with the right techniques, you can often repair them and restore functionality without the need for costly replacements. Here are some techniques for repairing damaged cables:

-

Splice and Tape: For minor cuts or tears in the insulation, you can splice the damaged section of the cable and cover it with electrical tape. Make sure to strip the insulation carefully, twist the conductors together, and securely tape the splice to prevent exposure to live wires.

-

Heat Shrink Tubing: Heat shrink tubing is an excellent option for repairing damaged insulation or providing additional protection to spliced wires. Slide a piece of heat shrink tubing over the damaged area, apply heat using a heat gun or lighter, and watch as the tubing shrinks and forms a tight seal around the repair.

-

Connector Replacement: If the damage is more extensive or located near a connector, consider replacing the connector instead of attempting to repair the cable. Cut off the damaged portion of the cable, strip the insulation, and install a new connector using crimping tools or soldering equipment.

-

Wire Nut Connection: Wire nuts are screw-on connectors designed for joining multiple wires together. If you need to splice wires together, twist the stripped ends of the wires together and secure them with a wire nut. Make sure the connection is tight and insulated to prevent electrical hazards.

-

Professional Repair Kits: For more complex repairs or situations where safety is a concern, consider using professional repair kits designed specifically for repairing damaged cables. These kits often include specialized tools, materials, and instructions for safely and effectively repairing various types of cable damage.

Remember to always prioritize safety when repairing damaged cables, and consult a professional electrician if you’re unsure about the proper techniques or procedures. With the right tools and know-how, you can tackle cable repairs with confidence and keep your electrical system running smoothly.

Future Trends in Electric Wiring Technology

Innovations in Cable Materials and Designs

Electric wiring technology has come a long way since the early days of rubber-insulated wires. Today, rapid advancements in materials science and engineering are driving innovation in cable materials and designs, paving the way for safer, more efficient, and environmentally friendly electrical systems. Here are some exciting trends shaping the future of electric wiring technology:

-

Advancements in Insulation Materials: Traditional insulation materials like PVC and rubber are being replaced with newer, more sustainable alternatives. For example, thermoplastic materials such as polyethylene and cross-linked polyethylene (XLPE) offer improved resistance to heat, moisture, and mechanical stress, making them ideal for a wide range of applications.

-

High-Temperature Wiring: As the demand for high-power electronics and renewable energy systems grows, there’s a need for wiring materials capable of withstanding extreme temperatures. Innovations in heat-resistant materials, such as ceramic-based composites and silicone rubber, are enabling the development of high-temperature wiring solutions for aerospace, automotive, and industrial applications.

-

Flexible and Lightweight Cables: Flexible and lightweight cables are becoming increasingly important for applications where space is limited or where mobility is required. New materials and manufacturing techniques, such as thin-wall extrusion and advanced polymers, are making it possible to produce cables that are both durable and highly flexible, without sacrificing performance.

-

Smart Wiring Technologies: The integration of sensors, microprocessors, and communication interfaces into electrical cables is opening up new possibilities for smart wiring systems. Smart cables can monitor environmental conditions, detect faults or anomalies, and communicate with other devices in the network, enabling real-time monitoring, diagnostics, and predictive maintenance.

-

Environmentally Friendly Options: With growing concerns about environmental sustainability, there’s a growing demand for eco-friendly wiring materials and manufacturing processes. Companies are developing cables made from renewable or recycled materials, as well as exploring greener alternatives to traditional insulation and jacketing compounds.

Integrating Smart Technology into Electrical Systems

The future of electric wiring technology isn’t just about improving materials and designs – it’s also about making electrical systems smarter and more connected than ever before. From smart homes to industrial automation, integrating smart technology into electrical systems offers numerous benefits in terms of energy efficiency, convenience, and safety. Here’s how smart technology is shaping the future of electrical systems:

-

Home Automation: Smart wiring systems enable homeowners to control lighting, heating, cooling, and other electrical devices remotely using smartphones, tablets, or voice commands. By integrating sensors and actuators into electrical cables, smart homes can adapt to occupants’ preferences, optimize energy usage, and enhance comfort and security.

-

Industrial IoT: In industrial settings, smart wiring systems can provide real-time monitoring and control of equipment, machinery, and infrastructure. By collecting and analyzing data from sensors embedded in electrical cables, manufacturers can optimize production processes, prevent equipment failures, and improve overall efficiency and productivity.

-

Building Management Systems: Smart wiring technology is revolutionizing building management systems, allowing facility managers to monitor and control electrical systems, HVAC, lighting, and security systems from a centralized dashboard. By integrating data from various sensors and devices, building managers can optimize energy usage, reduce operating costs, and ensure occupant comfort and safety.

-

Predictive Maintenance: Smart cables equipped with sensors can detect early signs of wear, overheating, or electrical faults, allowing maintenance teams to take proactive measures before equipment failures occur. By implementing predictive maintenance strategies, organizations can minimize downtime, extend equipment lifespan, and reduce maintenance costs.

-

Energy Management: Smart wiring systems enable precise monitoring and control of energy consumption in residential, commercial, and industrial settings. By analyzing energy usage patterns and optimizing load distribution, smart grids can reduce peak demand, lower electricity bills, and promote renewable energy integration.

As the world becomes increasingly interconnected, the integration of smart technology into electrical systems will play a crucial role in shaping the future of energy management, automation, and sustainability. By embracing these trends and innovations, we can build smarter, more efficient, and more resilient electrical infrastructure for generations to come.