How to Ring a Wire: Master Electrical Diagnostics

Understanding Wire Ringing Techniques

Exploring the Concept of “Ringing” in Wiring

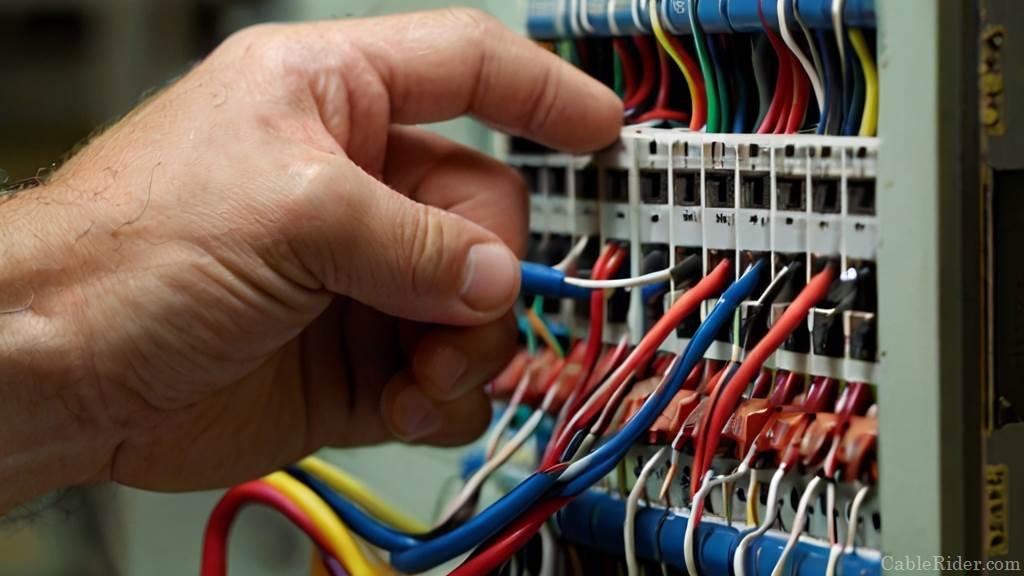

Picture this: you’re troubleshooting an electrical issue in your home. You suspect a wire might be the culprit, but how do you pinpoint the problem? That’s where wire ringing comes into play. But what exactly is wire ringing? In the realm of electrical work, “ringing” refers to the process of testing wires or cables to determine their continuity, integrity, and potential faults. It’s akin to sending out a signal along the wire and listening for a response to confirm that the circuit is complete and functional.

Contents

ToggleImportance of Ringing Wires in Electrical Work

Why does wire ringing matter? Well, imagine if you’re setting up a new lighting fixture in your living room. You connect all the wires, flip the switch, and… nothing happens. Frustrating, right? Without properly functioning wires, your electrical systems are like puzzle pieces that don’t fit together. By mastering the art of wire ringing, you gain the ability to diagnose and resolve electrical issues efficiently. Whether you’re a DIY enthusiast or a seasoned electrician, knowing how to ring wires can save you time, money, and headaches in the long run.

Now, let’s delve deeper into the intricacies of wire ringing and equip you with the knowledge to tackle electrical challenges with confidence.

-

Understanding Wire Continuity Testing: Before diving into wire ringing techniques, it’s crucial to grasp the concept of continuity testing. Continuity testing involves checking if an electrical circuit is complete by verifying the flow of current from one point to another. When a wire or cable is “rung,” it means you’re testing its continuity to ensure that electricity can flow freely without interruption. Think of it as tracing the path of least resistance to confirm that the circuit is intact.

-

Selecting the Right Tools for the Job: Like any skilled tradesperson, having the right tools at your disposal can make all the difference. When it comes to wire ringing, a multimeter is your best friend. This versatile device allows you to measure voltage, resistance, and continuity with precision. Before you start ringing wires, make sure your multimeter is set to the appropriate mode for continuity testing.

-

Probing Techniques for Accurate Results: Now that you’re armed with a multimeter, it’s time to get hands-on with wire ringing. Begin by identifying the wires you want to test, ensuring that the power source is turned off to prevent any accidents. With the multimeter set to continuity mode, gently touch the probes to either end of the wire or cable in question. Listen for the telltale beep or look for a change in the multimeter’s display, indicating that continuity has been established.

-

Interpreting Results and Troubleshooting: So, what do you do if your wire ringing efforts yield unexpected results? Don’t panic just yet. If your multimeter registers continuity where it shouldn’t, it could signal a short circuit or unintended connection between wires. Conversely, if there’s no continuity where there should be, it might indicate a break or open circuit in the wiring. Armed with this insight, you can methodically troubleshoot and address any issues that arise.

By mastering the art of wire ringing, you’re not just testing wires—you’re empowering yourself to tackle electrical challenges with confidence and precision. So, the next time you encounter a wiring dilemma, remember these techniques and ring on!

Essential Tools for Wire Ringing

Introduction to Multimeters for Wire Continuity Checking

Ever found yourself scratching your head over a faulty electrical connection? Wondering how to determine if a wire is carrying current or if it’s just dead weight? Say hello to your new best friend in the toolkit: the multimeter. But wait, what exactly is a multimeter, and how does it work its magic?

Multimeters are like the Swiss Army knives of the electrical world—compact, versatile, and indispensable. These handy gadgets are designed to measure various electrical properties, including voltage, current, and resistance. But perhaps one of their most underrated features is their ability to check wire continuity, also known as wire ringing.

Picture this scenario: you’re tackling a home improvement project that involves rewiring a light fixture. You’ve got all the wires laid out, but you’re not sure if they’re conducting electricity as they should. This is where the multimeter comes into play. By setting it to continuity mode and probing the wires, you can quickly determine if there’s a clear path for electricity to flow, ensuring that your DIY endeavors stay on track.

But not all multimeters are created equal. Let’s dive deeper into what sets them apart and how to choose the right one for your wire ringing tasks.

Choosing the Right Multimeter for Wire Ringing Tasks

With a plethora of multimeters on the market, finding the perfect match for your wire ringing needs can feel like navigating a maze. Fear not, fellow DIY enthusiasts, for we’re here to simplify the selection process.

-

Analog vs. Digital: The age-old debate rages on: analog or digital? Analog multimeters offer a traditional, needle-based display that some find easier to interpret. However, digital multimeters provide precise numerical readouts, making them ideal for complex measurements. For wire ringing tasks, digital multimeters often offer more features and accuracy.

-

Accuracy and Resolution: When it comes to wire ringing, accuracy is key. Look for a multimeter with a high degree of accuracy, typically expressed as a percentage of the reading. Additionally, pay attention to the meter’s resolution—the smallest increment it can detect. Higher resolution ensures that you can pinpoint even the slightest changes in continuity.

-

Continuity Mode and Audible Alerts: Not all multimeters come equipped with a dedicated continuity mode, so be sure to check for this feature. Continuity mode emits an audible beep when the circuit is complete, making it easy to identify connected wires without constantly glancing at the display. This hands-free functionality can be a game-changer when you’re elbows-deep in wires.

-

Durability and Build Quality: Let’s face it—electrical work can be rough on tools. Look for a multimeter with a sturdy build and durable components that can withstand the rigors of the job site. Rubberized grips, reinforced probes, and impact-resistant casings are all indicators of a multimeter built to last.

-

Additional Features: While wire ringing may be your primary concern, don’t overlook the value of additional features that can enhance your multimeter’s versatility. Look for functions like diode testing, capacitance measurement, and temperature sensing, which can come in handy for a variety of electrical tasks beyond wire continuity checking.

Armed with this knowledge, you’re now equipped to choose the perfect multimeter for your wire ringing adventures. So go ahead, take the plunge, and make your electrical projects a breeze with the right tool by your side. Happy wiring!

How to Ring Wires Using a Multimeter

Step-by-Step Guide to Checking Wire Continuity

Are you ready to unravel the mysteries hidden within your electrical wiring? With a trusty multimeter by your side, you can embark on a journey to uncover continuity issues and ensure your circuits are in tip-top shape. Let’s break down the process step by step:

-

Prepare Your Workspace: Before diving into wire ringing, make sure your work area is safe and well-lit. Turn off the power to the circuit you’ll be testing to avoid any accidents. Gather your multimeter, probes, and the wires you’ll be checking.

-

Set Up the Multimeter for Continuity Testing: Now it’s time to get your multimeter ready for action. Turn the dial to the continuity testing mode, usually denoted by a symbol that looks like a sound wave or a diode. If your multimeter has multiple continuity ranges, select the appropriate one for your testing needs.

-

Select the Proper Testing Mode: With your multimeter set to continuity mode, you’re almost ready to start ringing wires. But first, double-check that the testing mode is selected correctly. Some multimeters offer additional features like resistance or voltage testing, so ensure you’re in the right mode for wire continuity checking.

-

Touching Probes to Ensure Accurate Readings: Here comes the moment of truth—time to touch probes and see if your wires are up to snuff. Gently touch the probes to either end of the wire or cable you’re testing. Listen for the satisfying beep or look for a change in the multimeter’s display, indicating that continuity has been established.

Tips for Success:

-

Keep Probes Clean and Sharp: Dirty or worn-out probes can affect the accuracy of your readings. Regularly clean and inspect your probes to ensure they make good contact with the wires.

-

Be Mindful of Safety: Safety should always come first when working with electricity. Always turn off the power before testing wires, and never touch exposed conductors with bare hands.

-

Double-Check Your Connections: Sometimes, a loose connection or corroded terminal can mimic a continuity issue. Before jumping to conclusions, double-check all connections to ensure they’re secure and free of debris.

-

Test Multiple Points: For complex circuits or long runs of wiring, it’s a good idea to test multiple points along the path. This can help you pinpoint the exact location of any continuity issues and troubleshoot more effectively.

By following these steps and keeping these tips in mind, you’ll be well-equipped to ring wires like a pro. So go ahead, grab your multimeter, and embark on a journey of electrical discovery. Who knows what hidden secrets you’ll uncover along the way? Happy testing!

Common Issues Detected Through Wire Ringing

Identifying Faulty Wires and Connections

When it comes to electrical systems, even the smallest glitch can cause a ripple effect of problems. That’s why mastering the art of wire ringing is essential for anyone working with wires or cables. By identifying faulty wires and connections early on, you can prevent potential disasters down the line.

-

Loose Connections: One of the most common issues detected through wire ringing is loose connections. Over time, wires can become dislodged or corroded, resulting in poor conductivity and intermittent power supply. By ringing wires regularly, you can catch loose connections before they escalate into major issues.

-

Corrosion: Another culprit behind faulty connections is corrosion. Exposure to moisture or harsh environments can cause wires to corrode, inhibiting the flow of electricity. Through wire ringing, you can detect signs of corrosion early on and take steps to mitigate further damage.

-

Damaged Insulation: Wires with damaged insulation pose a significant risk of short circuits and electrical fires. By ringing wires, you can identify areas where the insulation has been compromised, allowing you to address the issue promptly and prevent potential hazards.

Breaks or Opens in the Wiring

Imagine a highway with a missing section of road—traffic comes to a standstill, chaos ensues, and no one gets to their destination. Similarly, breaks or opens in wiring can disrupt the flow of electricity and wreak havoc on your electrical systems. Here’s how wire ringing can help detect these issues:

-

Visual Inspection: While some breaks in wiring may be visible to the naked eye, others can be more elusive. By ringing wires, you can systematically test each segment of the wiring to pinpoint areas where continuity is interrupted.

-

Audible Alerts: Many multimeters feature an audible continuity alert that beeps when a complete circuit is detected. This feature can be invaluable when searching for breaks or opens in wiring, as it provides immediate feedback on the status of the circuit.

-

Resistance Measurements: In addition to continuity testing, multimeters can also measure resistance along a wire. A sudden increase in resistance may indicate the presence of a break or open in the wiring, prompting further investigation.

Short Circuits and Grounding Problems

Short circuits are like traffic jams in your electrical system—sudden, disruptive, and potentially dangerous. Whether caused by faulty wiring or human error, short circuits can lead to overheating, fires, and damage to your electrical devices. Here’s how wire ringing can help detect short circuits and grounding problems:

-

Abnormal Readings: When ringing wires, be on the lookout for abnormal readings or fluctuations in continuity. These could be indicative of a short circuit or improper grounding, signaling the need for further inspection.

-

Visual Inspection: In addition to using a multimeter, visually inspecting the wiring for signs of damage or exposed conductors can help identify potential short circuits. Look for melted insulation, burn marks, or charred areas, which may indicate a short circuit has occurred.

-

Isolation Testing: To pinpoint the source of a short circuit, you may need to isolate individual sections of wiring and test them separately. By systematically testing each segment, you can narrow down the location of the problem and take corrective action.

By familiarizing yourself with these common issues detected through wire ringing, you’ll be better equipped to troubleshoot electrical problems and ensure the safety and reliability of your electrical systems. So grab your multimeter and start ringing those wires—you never know what you might uncover!

Ringing Cables: Techniques and Considerations

Differentiating Between Wires and Cables

Ever wondered what sets wires apart from cables? While they may seem similar at first glance, there are some key differences to consider. Let’s break it down:

-

Wires: Think of wires as the building blocks of electrical systems—they’re single conductors typically made of copper or aluminum. Wires are used to carry electrical currents from one point to another and are often encased in insulation to prevent electrical shocks or short circuits.

-

Cables: On the other hand, cables are like the superhighways of the electrical world. They consist of multiple wires bundled together and encased in a protective sheath. Cables are designed to transmit power or data over longer distances and are commonly used in applications like telecommunications, networking, and power distribution.

Understanding the distinction between wires and cables is crucial when it comes to ringing techniques and considerations.

Understanding Cable Structures and Components

Now that we’ve clarified the difference between wires and cables, let’s take a closer look at cable structures and components:

-

Conductors: At the heart of every cable are the conductors—individual wires that carry electrical signals. These conductors are typically made of copper or aluminum due to their excellent conductivity properties.

-

Insulation: Surrounding the conductors is insulation, which serves to protect them from external elements and prevent electrical leakage. Insulation materials can vary depending on the cable’s intended application, with options like PVC, rubber, or polyethylene commonly used.

-

Sheath: The outer layer of a cable is known as the sheath or jacket. This protective covering provides additional insulation and shields the internal components from mechanical damage, moisture, and environmental hazards.

By understanding the components that make up a cable, you’ll be better equipped to assess its integrity and performance through wire ringing techniques.

Techniques for Accurate Cable Ringing

Now that you’re familiar with cable structures and components, let’s explore some techniques for accurate cable ringing:

-

Segmented Testing: When ringing cables, it’s often helpful to break the testing process down into segments. Start by testing each individual conductor to ensure continuity, then move on to testing the cable as a whole. This segmented approach can help pinpoint any issues more efficiently.

-

Tone Tracing: In addition to continuity testing, consider using a tone tracer for cable ringing. A tone tracer emits a distinct audio tone along the length of the cable, allowing you to trace its path and identify breaks or faults. This technique is particularly useful for locating hidden cables or identifying specific wires within a bundle.

-

Visual Inspection: Don’t underestimate the power of a visual inspection when ringing cables. Examine the cable for any signs of damage, such as cuts, kinks, or exposed conductors. These visual cues can provide valuable insight into the condition of the cable and help guide your testing efforts.

By incorporating these techniques into your cable ringing process, you’ll be able to assess the integrity of cables more accurately and troubleshoot any issues with confidence. So grab your multimeter, roll up your sleeves, and start ringing those cables—it’s time to uncover the secrets hidden within!

Practical Applications: Ringing Wiring in an Apartment

Assessing Electrical Systems in Residential Settings

So, you’ve just moved into a new apartment, and everything seems perfect—until you encounter an electrical issue. From flickering lights to malfunctioning outlets, residential electrical problems can throw a wrench into your plans. But fear not, for wire ringing is here to save the day. Let’s explore how this handy technique can help you assess electrical systems in your apartment:

-

Safety First: Before you dive into any electrical work, it’s crucial to prioritize safety. Turn off the power to the area you’ll be inspecting to avoid any accidents or shocks. Remember, it’s better to be safe than sorry when dealing with electricity.

-

Visual Inspection: Start by visually inspecting your apartment’s electrical system for any obvious signs of damage or wear. Look for frayed wires, discolored outlets, or sparking switches—all of which could indicate underlying issues that require further investigation.

-

Multimeter Magic: Armed with a multimeter set to continuity mode, you can begin ringing wires to assess their integrity. Test outlets, switches, and light fixtures to ensure that electricity is flowing properly and that there are no breaks or shorts in the wiring.

By assessing the electrical systems in your apartment with wire ringing techniques, you can identify potential issues early on and take proactive steps to address them before they escalate into major problems. Now, let’s delve deeper into specific aspects of wiring assessment.

Locating Wiring Routes and Junction Boxes

Ever wondered what lies behind the walls of your apartment? With wire ringing techniques, you can uncover the hidden pathways of electrical wiring and locate important junction boxes. Here’s how:

-

Follow the Traces: Start by tracing the visible wiring in your apartment to identify its routes and connections. Look for wires running along baseboards, through walls, and into ceiling fixtures—these pathways can give you valuable insights into the layout of your electrical system.

-

Probe and Listen: Use your multimeter’s continuity mode to probe walls and ceilings for hidden wiring. By systematically testing different areas, you can map out the locations of junction boxes and electrical connections, allowing you to better understand the overall wiring scheme of your apartment.

Detecting Wiring Issues in Apartment Installations

From faulty outlets to overloaded circuits, apartment electrical systems can be prone to a variety of issues. By employing wire ringing techniques, you can detect and troubleshoot common wiring problems with ease:

-

Outlet Testing: Test each outlet in your apartment for proper wiring and functionality. Look for signs of loose connections or overheating, which could indicate underlying issues that need attention.

-

Circuit Breaker Inspection: Take a closer look at your apartment’s circuit breaker panel to ensure that circuits are properly labeled and that breakers are not overloaded. Use your multimeter to test the continuity of individual circuits and identify any potential faults.

-

Light Fixture Checks: Don’t forget to inspect light fixtures for signs of wiring issues, such as flickering lights or dimming bulbs. Test the continuity of wires leading to fixtures to ensure they’re properly connected and functioning as they should.

By diligently assessing wiring routes, locating junction boxes, and detecting common wiring issues in your apartment, you can maintain a safe and reliable electrical system that keeps your home running smoothly. So don’t let electrical problems dim your apartment living experience—grab your multimeter and start ringing those wires today!

Advanced Insights into Wire Ringing

Exploring Additional Testing Methods Beyond Multimeters

So you’ve mastered the art of wire ringing with a multimeter, but did you know there are additional testing methods that can take your diagnostics to the next level? Let’s delve into some advanced techniques for uncovering hidden electrical issues:

-

Capacitance Testing: Capacitance testing involves measuring the ability of a wire or cable to store electrical energy. By analyzing capacitance levels, you can identify issues such as insulation breakdown or moisture ingress that may not be detectable through traditional continuity testing.

-

Impedance Testing: Impedance testing evaluates the total opposition to current flow in a circuit, including resistance, capacitance, and inductance. This comprehensive approach can help pinpoint complex wiring problems and provide insights into the overall health of your electrical system.

-

Time Domain Reflectometry (TDR): TDR is a specialized testing method that sends short pulses of electrical energy down a wire and measures the time it takes for the signal to bounce back. By analyzing these reflections, TDR can identify the location and severity of faults such as breaks, opens, or impedance mismatches in wiring systems.

Using Tone Generators for Tracing Wires

Ever wished you had a magic wand that could instantly trace the path of a wire through walls and ceilings? Enter the tone generator—a versatile tool that emits a distinct audio tone along the length of a wire, allowing you to trace its route with ease. Here’s how it works:

-

Pairing with a Probe: To use a tone generator, simply connect it to one end of the wire you wish to trace and attach a probe to the other end. As the tone generator sends out its signal, move the probe along the wire’s pathway, listening for changes in tone intensity or frequency. This intuitive method allows you to quickly locate wires hidden behind walls or buried within conduits.

-

Multiple Tones for Different Wires: Some tone generators offer the ability to generate multiple tones simultaneously, allowing you to trace multiple wires at once. This feature is particularly useful in complex wiring environments where multiple circuits may be present.

Employing Thermal Imaging for Detecting Hotspots in Wiring Systems

When it comes to electrical systems, heat is often a telltale sign of trouble brewing beneath the surface. Thermal imaging cameras offer a non-invasive way to detect hotspots and potential issues in wiring systems:

-

Visualizing Temperature Variations: Thermal imaging cameras detect infrared radiation emitted by objects based on their temperature. By scanning electrical components and wiring systems with a thermal camera, you can visualize temperature variations that may indicate overheating, loose connections, or other potential hazards.

-

Early Warning Signs: Identifying hotspots early on can help prevent electrical fires, equipment damage, and costly downtime. By regularly inspecting wiring systems with a thermal imaging camera, you can proactively address issues before they escalate into serious problems.

By exploring these advanced insights into wire ringing, you can expand your diagnostic capabilities and gain a deeper understanding of your electrical systems. Whether you’re troubleshooting a complex wiring issue or conducting routine maintenance, these advanced techniques can help you keep your electrical systems running smoothly and safely. So grab your tools and start exploring the hidden world of wires—it’s time to unlock the secrets of your electrical system!