Which Way Does the Engine Spin? Unveiling Myths

Understanding Engine Rotation Direction

Exploring the Basics of Engine Rotation

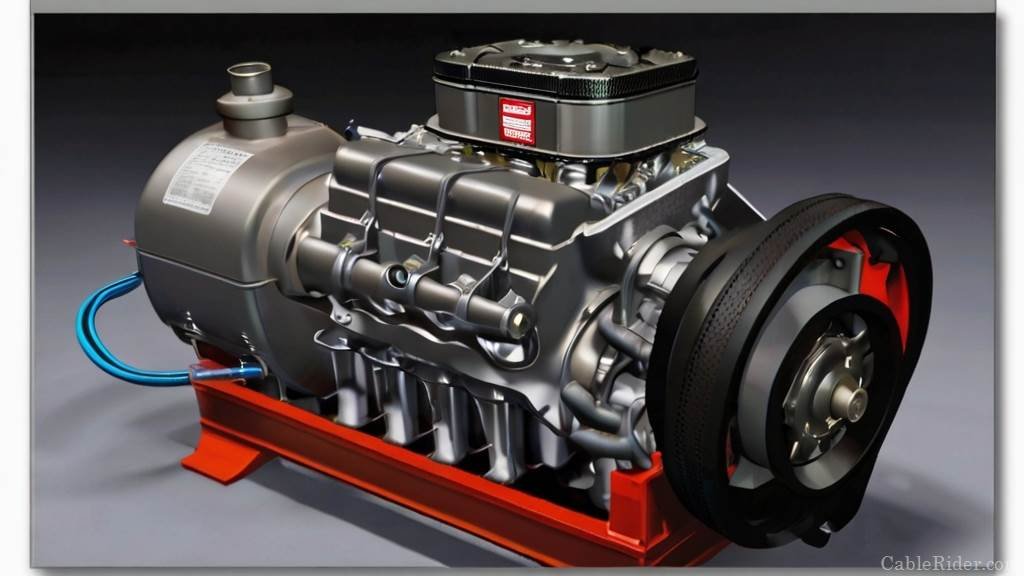

Have you ever wondered which way your car’s engine spins? Understanding the fundamental concept of engine rotation is like unraveling the mystery beneath the hood. Engines, whether powering your car or lawnmower, rotate in a specific direction to generate power. This rotation is vital for the engine’s functionality and overall performance.

Contents

ToggleThe engine’s rotation refers to the direction in which the crankshaft turns. The crankshaft is a key component responsible for converting the reciprocating motion of pistons into rotational motion. As the pistons move up and down within the cylinders, they transfer energy to the crankshaft, causing it to rotate.

Significance of Engine Rotation Direction

But why does it matter which way the engine spins? Well, the direction of rotation directly impacts various aspects of engine operation, from ignition timing to torque output. In most cases, engines rotate either clockwise (CW) or counterclockwise (CCW), also known as reverse rotation.

The significance of engine rotation direction becomes apparent when considering factors such as camshaft and distributor rotation, which are synchronized with the crankshaft’s motion. Additionally, understanding rotation direction is crucial for diagnosing and troubleshooting engine-related issues.

In a typical automotive engine, the rotation direction determines the firing order of the cylinders and the timing of fuel injection and spark ignition. This, in turn, affects engine performance, fuel efficiency, and emissions. Incorrect rotation direction can lead to engine misfires, reduced power output, and potential damage to internal components.

Key Takeaways

- The engine’s rotation direction is determined by the crankshaft’s motion.

- Clockwise (CW) and counterclockwise (CCW) rotation directions are common.

- Rotation direction influences ignition timing, firing order, and overall engine performance.

- Understanding rotation direction is essential for diagnosing engine issues and optimizing performance.

In essence, grasping the basics of engine rotation direction is like deciphering the engine’s language. It provides valuable insights into how the engine operates and empowers drivers and mechanics alike to ensure optimal performance and reliability. So, the next time you start your engine, take a moment to appreciate the intricate dance of motion happening beneath the surface.

Factors Influencing Engine Spin Direction

Engine Design Variations

When it comes to the direction in which an engine spins, there’s no one-size-fits-all answer. Engine design plays a significant role in determining the rotation direction. Different types of engines, from inline to V-configurations, exhibit variations in rotation direction based on their internal layout.

For example, inline engines, where all cylinders are aligned in a single row, typically rotate in one direction, either clockwise or counterclockwise. On the other hand, V-configured engines, with cylinders arranged in a V-shaped pattern, may rotate in the opposite direction, depending on the specific design.

Additionally, factors such as the arrangement of pistons, crankshaft configuration, and placement of timing components can influence the rotation direction. Engine manufacturers carefully engineer these elements to ensure optimal performance and efficiency while considering factors like balance and vibration.

Ignition Timing and Firing Order Influence

Ignition timing and firing order are critical aspects of engine operation that directly impact rotation direction. The firing order dictates the sequence in which cylinders receive spark ignition, while ignition timing determines when the spark occurs relative to the piston’s position.

These factors are intricately linked to rotation direction because they affect the timing of combustion events within the engine. In a typical four-stroke engine, the firing order is designed to optimize power delivery and minimize vibrations.

Moreover, the rotation direction must align with the firing order to ensure proper synchronization between the camshaft, distributor (or ignition coils), and crankshaft. Any deviation from the intended rotation direction can lead to misfires, reduced power output, and potential damage to engine components.

Key Takeaways

- Engine design variations, including inline and V-configurations, influence rotation direction.

- Factors such as piston arrangement and crankshaft configuration play a role in determining rotation direction.

- Ignition timing and firing order are crucial factors that influence rotation direction and must be synchronized for optimal engine performance.

In summary, understanding the factors that influence engine spin direction requires a deep dive into engine design and operational principles. By considering elements such as layout, timing, and synchronization, engineers can ensure that engines operate smoothly and efficiently, regardless of their rotation direction. So, the next time you marvel at the complexity of your car’s engine, remember the intricate dance of components that dictate its spin direction.

Clockwise vs. Counterclockwise Rotation

Impact of Rotation Direction on Engine Performance

The direction in which an engine rotates, whether clockwise or counterclockwise, can have a profound impact on its performance characteristics. This influence extends across various aspects of engine operation, including power output, efficiency, and even vehicle dynamics.

Engines designed to rotate clockwise typically follow a specific firing order and timing sequence optimized for this direction. Conversely, counterclockwise rotation engines feature their own unique configurations tailored to this rotation direction. These differences can affect factors such as torque delivery, throttle response, and overall drivability.

Moreover, rotation direction plays a role in engine balance and vibration. Engines spinning in one direction may exhibit different levels of smoothness compared to their counterparts rotating in the opposite direction. This difference in balance can influence vehicle comfort and refinement, particularly in high-performance applications where precision and smoothness are paramount.

Applications in Different Engine Types

The choice between clockwise and counterclockwise rotation is not arbitrary but rather dictated by specific applications and engineering requirements. For instance, marine engines often utilize counterclockwise rotation due to propeller design and torque considerations. In contrast, many automotive engines rotate clockwise to align with transmission and drivetrain configurations.

Furthermore, aircraft engines present another interesting case where rotation direction is carefully selected based on factors like propeller efficiency and torque distribution. While some aircraft engines rotate clockwise, others, particularly radial engines, may rotate counterclockwise to optimize performance in flight.

In industrial applications, such as power generation and machinery, rotation direction is chosen based on operational requirements and compatibility with other equipment. Whether driving pumps, generators, or manufacturing machinery, engineers must consider rotation direction to ensure seamless integration and optimal performance.

Key Takeaways

- Rotation direction significantly influences engine performance and characteristics.

- Factors such as firing order, timing, and balance are affected by rotation direction.

- Different applications, from automotive to marine and aerospace, dictate specific rotation directions based on engineering requirements and operational considerations.

In conclusion, the choice between clockwise and counterclockwise rotation is not a matter of preference but rather a carefully considered engineering decision. By understanding the impact of rotation direction on engine performance and its applications across various industries, engineers can design and optimize engines to meet specific needs and challenges. So, the next time you start your engine or board a plane, remember the intricate dance of rotation direction shaping your journey.

Determining Engine Spin Direction

Methods for Identifying Engine Rotation

Determining the spin direction of an engine is essential for proper operation and maintenance. Fortunately, several methods can help identify the rotation direction quickly and accurately.

1. Manufacturer Documentation

One of the most reliable ways to determine engine rotation direction is to consult the manufacturer’s documentation. Vehicle manuals or engine specifications often provide detailed information about rotation direction, along with other essential details about the engine.

2. Visual Inspection

A simple visual inspection can also reveal clues about the engine’s rotation direction. Observing the arrangement of components such as the distributor, timing marks, and accessory drive belts can provide valuable insights. In many cases, manufacturers design these components to rotate in a specific direction, indicating the engine’s spin direction.

3. Crankshaft Rotation

Another method involves manually rotating the crankshaft to observe its motion. By carefully turning the crankshaft in the direction of engine rotation, mechanics can feel the resistance and direction of rotation. This hands-on approach allows for a tactile understanding of the engine’s spin direction.

4. Timing Light

Using a timing light can help confirm the rotation direction by illuminating timing marks on the crankshaft pulley or flywheel. By connecting the timing light to the spark plug wire and aiming it at the timing marks, mechanics can observe the timing advance and confirm the rotation direction.

Importance in Maintenance and Repair

Understanding the engine’s spin direction is crucial for various maintenance and repair tasks, ensuring proper operation and longevity of the engine.

1. Timing and Firing Order Adjustment

Correctly setting ignition timing and firing order requires knowledge of the engine’s rotation direction. Improper timing or firing order can lead to misfires, reduced performance, and potential damage to engine components. By accurately determining the rotation direction, mechanics can perform adjustments with confidence and precision.

2. Belt and Pulley Alignment

Proper alignment of belts and pulleys is essential for efficient power transmission and prevention of premature wear. The rotation direction of the engine determines the orientation of these components, ensuring optimal alignment and tension. Mechanics must identify the rotation direction to install belts and pulleys correctly during maintenance and repair procedures.

3. Troubleshooting Engine Issues

When diagnosing engine problems, knowing the rotation direction can help narrow down potential causes. Certain issues, such as timing belt or distributor malfunctions, may be rotation-direction-specific. By correctly identifying the rotation direction, mechanics can efficiently diagnose and address engine issues, minimizing downtime and costly repairs.

4. Preventive Maintenance

Regular maintenance tasks, such as oil changes and inspections, can be affected by the engine’s rotation direction. Mechanics must follow manufacturer recommendations specific to the rotation direction to ensure proper lubrication and component wear. By adhering to these guidelines, mechanics can extend the engine’s lifespan and prevent premature failure.

Key Takeaways

- Methods for identifying engine rotation direction include consulting manufacturer documentation, visual inspection, manual crankshaft rotation, and using a timing light.

- Understanding rotation direction is essential for adjusting timing and firing order, aligning belts and pulleys, troubleshooting engine issues, and performing preventive maintenance.

- By accurately determining the rotation direction, mechanics can ensure proper engine operation, minimize downtime, and optimize performance and longevity.

In summary, determining engine spin direction is a fundamental aspect of engine maintenance and repair. By utilizing various identification methods and understanding its importance in engine operation, mechanics can effectively address issues and ensure the reliable performance of engines across various applications. So, the next time you pop the hood, remember the significance of spin direction in keeping your engine running smoothly.

Historical Evolution of Engine Rotation

Early Engine Designs and Rotation Direction

The history of engine rotation direction is a fascinating journey through the evolution of mechanical engineering. In the early days of engine development, there was no standardized rotation direction, leading to a variety of configurations and designs.

1. Reciprocating Engines

The earliest reciprocating engines, such as those used in steam engines and early internal combustion engines, often featured simple designs with basic components. Without strict guidelines or standards, engineers experimented with different rotation directions based on individual preferences and practical considerations.

2. Variable Rotation Direction

During this period, it was not uncommon to find engines with variable rotation directions, where the rotation could be reversed manually or through mechanical adjustments. This flexibility allowed operators to adapt engines to specific tasks or operating conditions, such as driving different types of machinery or vehicles.

3. Experimental Designs

As engine technology advanced, so did the exploration of different rotation directions and their effects on performance. Engineers and inventors conducted numerous experiments to optimize engine design and rotation direction for efficiency, power output, and reliability.

Technological Advancements and Changes

The evolution of engine rotation direction took a significant leap forward with technological advancements and standardized manufacturing processes. As engines became more sophisticated, designers began to prioritize factors such as efficiency, durability, and compatibility with other components.

1. Standardization

With the rise of the automotive industry in the late 19th and early 20th centuries, there was a growing need for standardization in engine design and rotation direction. Manufacturers began to adopt common practices and specifications, leading to widespread use of clockwise and counterclockwise rotation in various engine types.

2. Optimization for Performance

Technological advancements, such as improvements in materials, machining techniques, and combustion processes, enabled engineers to optimize engine designs for specific rotation directions. This optimization resulted in increased power output, reduced emissions, and enhanced fuel efficiency, driving the evolution of engine technology forward.

3. Integration with Transmission Systems

As vehicles became more complex, the integration of engines with transmission systems became a critical consideration. Engine rotation direction needed to align with the design of transmission components, such as gears and shafts, to ensure smooth operation and efficient power transfer.

Key Takeaways

- The early history of engine rotation direction was characterized by experimentation and variability.

- Technological advancements and standardization led to the widespread adoption of clockwise and counterclockwise rotation in modern engine designs.

- Engine rotation direction became optimized for performance, efficiency, and compatibility with transmission systems, driving the evolution of engine technology.

In summary, the historical evolution of engine rotation direction reflects the ingenuity and innovation of engineers throughout the centuries. From early experimental designs to standardized modern engines, the journey has been marked by continuous improvement and adaptation to meet the demands of evolving industries and technologies. So, the next time you start your car or operate a piece of machinery, remember the rich history behind the rotation direction powering your engine.

Common Misconceptions and Myths

Debunking Misunderstandings about Engine Rotation

In the realm of engines, there are several common misconceptions and myths surrounding rotation direction and its implications. Let’s delve into some of these misunderstandings and separate fact from fiction.

1. Myth: Engines Only Rotate Clockwise

Contrary to popular belief, engines can rotate in both clockwise and counterclockwise directions. While clockwise rotation is more prevalent in many automotive applications, counterclockwise rotation is also utilized in certain engines, particularly in marine and industrial settings.

2. Myth: Rotation Direction Affects Engine Power

Some people mistakenly believe that the rotation direction of an engine significantly impacts its power output or performance. In reality, rotation direction is just one of many factors influencing engine operation. While improper rotation direction can lead to issues such as timing misalignment, it does not inherently affect the engine’s power capabilities.

3. Myth: Changing Rotation Direction Improves Performance

There’s a common misconception that altering the rotation direction of an engine can enhance its performance or efficiency. In truth, changing the rotation direction requires significant modifications to internal components and synchronization with other engine systems. Attempting to reverse the rotation direction without proper engineering considerations can result in severe damage to the engine.

Addressing Popular Beliefs and Fallacies

Let’s address some more popular beliefs and fallacies surrounding engine rotation direction to dispel any lingering doubts.

1. Fallacy: Counterclockwise Rotation is Better for Fuel Efficiency

While some argue that counterclockwise rotation engines are more fuel-efficient, there is no direct correlation between rotation direction and fuel consumption. Fuel efficiency is primarily determined by factors such as engine design, combustion efficiency, and driving conditions, rather than rotation direction alone.

2. Fallacy: Clockwise Rotation Causes Engine Wear

Another common fallacy is the belief that clockwise rotation engines are more prone to wear and tear compared to counterclockwise rotation engines. In reality, proper maintenance and lubrication are the primary factors influencing engine longevity, regardless of rotation direction. Both clockwise and counterclockwise rotation engines can achieve long service lives with regular care and upkeep.

3. Fallacy: Rotation Direction Determines Engine Sound

While it’s true that engine sound can vary depending on factors such as firing order and exhaust configuration, rotation direction alone does not dictate the engine’s sound profile. Engine noise is influenced by a combination of factors, including engine design, displacement, and exhaust system tuning, rather than rotation direction alone.

Key Takeaways

- Common misconceptions and myths surround engine rotation direction and its implications.

- Debunking misunderstandings helps clarify the role of rotation direction in engine operation.

- Engine performance and characteristics are influenced by various factors beyond rotation direction alone.

In conclusion, debunking common misconceptions and myths about engine rotation direction is essential for fostering a better understanding of engine operation and maintenance. By addressing popular beliefs and fallacies, we can promote accurate information and empower individuals to make informed decisions regarding engine care and usage. So, the next time you hear a myth about engine rotation direction, remember to question it and seek out the truth.

Future Perspectives and Innovations

Emerging Trends in Engine Design

The future of engine design holds exciting possibilities as engineers and researchers continue to push the boundaries of innovation. Let’s explore some of the emerging trends shaping the landscape of engine technology.

1. Electrification

With a growing emphasis on sustainability and reducing carbon emissions, electrification is a major trend in engine design. Hybrid and electric powertrains are becoming increasingly common, offering improved efficiency and lower environmental impact compared to traditional internal combustion engines.

2. Lightweight Materials

Advancements in materials science are enabling the development of engines constructed from lightweight and high-strength materials such as carbon fiber, aluminum alloys, and composites. These materials help reduce overall vehicle weight, improving fuel efficiency and performance.

3. Advanced Combustion Technologies

Innovations in combustion technology, such as homogeneous charge compression ignition (HCCI) and lean-burn engines, promise greater fuel efficiency and lower emissions. These advanced combustion techniques optimize the combustion process for improved efficiency and reduced environmental impact.

Potential Impacts on Rotation Direction

As engine design evolves to embrace new technologies and innovations, the traditional notion of rotation direction may undergo changes or adaptations. Let’s explore how emerging trends in engine design could potentially impact rotation direction.

1. Integration with Electric Motors

With the rise of hybrid and electric powertrains, the role of traditional internal combustion engines may shift from primary power sources to range extenders or supplementary power generators. This shift could lead to changes in rotation direction requirements or configurations to optimize integration with electric motors and drivetrains.

2. Modular Engine Platforms

Modular engine platforms, where components are interchangeable and adaptable to different vehicle types and powertrain configurations, could influence rotation direction considerations. Engine designs may incorporate flexible rotation direction capabilities to accommodate various vehicle architectures and applications.

3. Autonomous Vehicle Integration

The advent of autonomous vehicles presents unique challenges and opportunities for engine design. As vehicles become more automated and interconnected, rotation direction considerations may evolve to prioritize compatibility with autonomous driving systems and vehicle control algorithms.

Key Takeaways

- Emerging trends in engine design include electrification, lightweight materials, and advanced combustion technologies.

- The future of rotation direction in engine design may be influenced by factors such as integration with electric motors, modular platforms, and autonomous vehicle technology.

In summary, the future of engine design holds promise for exciting innovations and advancements that could reshape the automotive industry. As engineers continue to explore new technologies and solutions, the role of rotation direction in engine design may evolve to meet the demands of a rapidly changing automotive landscape. So, stay tuned for the next chapter in the ongoing evolution of engine technology.