Types of Gearboxes: Unveiling Innovation and Efficiency

Understanding the Role of Gearboxes

Importance of Gearboxes in Mechanical Systems

Gearboxes are the unsung heroes of the mechanical world, silently powering everything from cars to industrial machinery with precision and efficiency. But why are they so crucial? Picture this: you’re driving down the highway, smoothly shifting gears as you accelerate or decelerate. That seamless transition? It’s all thanks to the gearbox. In essence, gearboxes are the translators of motion, converting the rotational energy from an engine into different speeds and torques tailored to specific tasks.

Contents

ToggleCore Functions of Gearboxes in Machinery

Now, let’s delve into the nitty-gritty of what gearboxes actually do. At their core, gearboxes serve three primary functions: speed reduction, speed increase, and torque multiplication. When you press down on the gas pedal of your car, the engine revs up, generating high-speed rotational energy. However, this energy alone isn’t always suitable for driving. Here’s where the gearbox steps in. By employing an intricate arrangement of gears with varying sizes, gearboxes can either slow down the rotational speed from the engine to match the desired output speed (as in the case of lower gears for climbing hills) or amplify it for swift acceleration (like when cruising on the highway in higher gears). Additionally, gearboxes can also increase torque, the rotational force that drives machinery. This torque multiplication is crucial for heavy-duty applications like towing or lifting heavy loads, where raw power is paramount.

Gearboxes are akin to the maestros of a mechanical orchestra, orchestrating the harmonious interplay of speed and force to ensure optimal performance across a myriad of applications. Whether it’s powering a humble lawnmower or propelling a colossal freight train, gearboxes are the silent champions working tirelessly behind the scenes to keep our world moving forward.

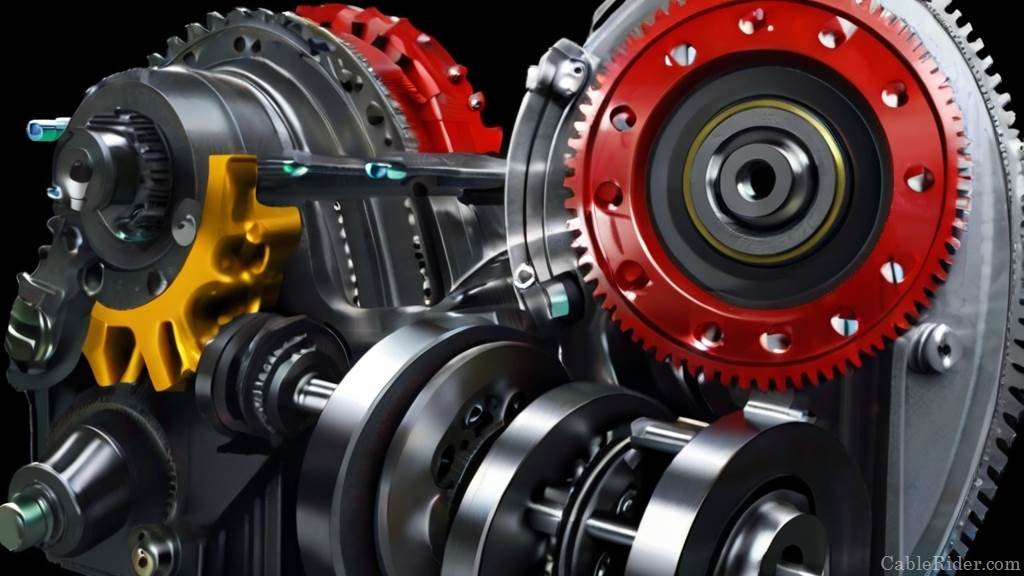

Anatomy of a Gearbox

Components of a Typical Gearbox

Gearboxes are intricate assemblies comprised of several essential components, each playing a crucial role in ensuring smooth and efficient power transmission. Let’s take a closer look at the key elements that make up a typical gearbox.

Gears and Gear Sets

At the heart of every gearbox are the gears themselves. These toothed wheels come in various shapes and sizes, each serving a specific purpose in the transmission process. From the familiar spur gears found in manual transmissions to the more complex helical and bevel gears used in heavy-duty industrial applications, the choice of gear type depends on factors such as load capacity, noise levels, and efficiency. Gear sets, comprised of multiple gears meshing together, form the backbone of gearboxes, allowing for the precise adjustment of speed and torque.

Shafts and Bearings

Connecting the gears and transmitting their rotational motion are the shafts within the gearbox. These shafts, typically made of hardened steel for durability, serve as the conduits through which power flows from the input to the output. Surrounding these shafts are bearings, which provide support and reduce friction, ensuring smooth rotation. Bearings come in various designs, including ball bearings and roller bearings, each optimized for specific load conditions and operating environments.

Lubrication Systems

Just like the engine in your car needs oil to keep its moving parts running smoothly, gearboxes rely on lubrication systems to minimize wear and tear and dissipate heat. Oil or grease is circulated throughout the gearbox, forming a thin film between moving components to reduce friction and prevent metal-to-metal contact. Additionally, lubricants help carry away heat generated during operation, maintaining optimal operating temperatures and prolonging the lifespan of the gearbox.

Exploring Gear Ratios and Transmission Systems

One of the defining features of gearboxes is their ability to alter the speed and torque of rotational motion through gear ratios. Gear ratios, expressed as the ratio of the number of teeth on the driving gear to the number of teeth on the driven gear, determine how much the rotational speed and torque are amplified or reduced. By selecting the appropriate gear ratio, gearboxes can adapt to various operating conditions, whether it’s providing high torque for heavy lifting or achieving maximum speed for high-performance applications.

Transmission systems, which encompass the entire mechanism for shifting gears, play a crucial role in delivering power from the engine to the wheels (or other output devices). In manual transmissions, this typically involves the use of a clutch mechanism to disengage and engage gears, allowing for seamless gear changes. Automatic transmissions, on the other hand, employ sophisticated hydraulic and electronic systems to automatically select the optimal gear ratio based on driving conditions.

In summary, the anatomy of a gearbox is a testament to the ingenuity of mechanical engineering, with each component working in harmony to deliver precise and reliable power transmission. From gears and shafts to lubrication systems and transmission mechanisms, every aspect of the gearbox is meticulously designed to ensure smooth operation and long-lasting performance.

Types of Gearboxes Based on Design

Manual Gearboxes

Manual gearboxes, also known as standard transmissions, put the power of gear shifting directly into the hands (and feet) of the driver. These gearboxes require the driver to manually engage and disengage gears using a gear shift and clutch pedal. While they may seem old-fashioned compared to their automatic counterparts, manual gearboxes offer several advantages, including greater control over the vehicle’s acceleration and deceleration, as well as improved fuel efficiency. Plus, there’s just something inherently satisfying about the tactile feedback of shifting gears yourself.

Automatic Gearboxes

Automatic gearboxes, on the other hand, take the hassle out of shifting gears by automatically selecting the appropriate gear ratio based on driving conditions. With no need for manual intervention, drivers can focus more on the road ahead, making automatic gearboxes particularly popular in congested urban environments. While they may sacrifice a bit of fuel efficiency compared to manual transmissions, the convenience they offer is undeniable. Plus, modern advancements in automatic transmission technology have significantly narrowed the efficiency gap, making them a viable option for drivers of all preferences.

Continuously Variable Transmission (CVT)

Continuously Variable Transmission, or CVT, represents a departure from traditional gearboxes altogether. Instead of discrete gear ratios, CVTs utilize a system of pulleys and belts to seamlessly adjust the transmission ratio, providing a theoretically infinite number of gear ratios. This results in a smoother and more efficient driving experience, with the engine able to operate at its optimal RPM range across a wide range of speeds. CVTs are particularly well-suited for applications where smooth acceleration and fuel efficiency are paramount, such as hybrid vehicles and compact cars.

Dual-Clutch Transmission (DCT)

Dual-Clutch Transmission, or DCT, combines the best of both worlds from manual and automatic gearboxes. By employing two separate clutches—one for odd-numbered gears and one for even-numbered gears—DCTs are able to pre-select the next gear, resulting in lightning-fast gear changes without any interruption in power delivery. This makes DCTs popular among performance enthusiasts, as they offer the crisp, responsive shifts of a manual gearbox with the convenience of an automatic. Additionally, DCTs are often more fuel-efficient than traditional automatic transmissions, making them an attractive option for eco-conscious drivers as well.

Automated Manual Transmission (AMT)

Automated Manual Transmission, or AMT, bridges the gap between manual and automatic gearboxes by automating the clutch and gear shift processes. Unlike traditional automatic transmissions, which use a torque converter to transmit power, AMTs retain the simplicity and mechanical efficiency of manual transmissions, with the addition of an automated clutch actuation system. This allows for smoother and more consistent shifting compared to traditional manual gearboxes, without sacrificing the engagement and control that manual transmissions offer. AMTs are commonly found in entry-level vehicles and commercial applications, where cost-effectiveness and ease of use are paramount.

In summary, the world of gearboxes is diverse and ever-evolving, with each type offering its own unique blend of performance, efficiency, and convenience. Whether you prefer the hands-on engagement of a manual gearbox or the seamless shifts of an automatic, there’s a gearbox out there to suit every driving style and preference.

Classifying Gearboxes by Purpose

Automotive Gearboxes

Automotive gearboxes are the workhorses of the road, providing the necessary torque and speed adjustments to propel vehicles forward with ease. But did you know that not all automotive gearboxes are created equal? Indeed, the requirements for passenger cars, trucks, and racing vehicles can vary significantly, leading to the development of specialized gearbox designs tailored to each application.

Different Requirements for Passenger Cars, Trucks, and Racing Vehicles

Passenger cars, with their focus on comfort and fuel efficiency, typically utilize automatic or manual transmissions with a range of gear ratios optimized for city driving and highway cruising. These gearboxes prioritize smooth shifts and low-end torque for responsive acceleration, making them ideal for everyday commuting.

Trucks, on the other hand, demand ruggedness and durability to handle heavy loads and rough terrain. As such, they often employ manual transmissions with additional low gears for hauling and towing. These gearboxes are built to withstand the rigors of long-haul driving while providing the necessary torque multiplication to tackle steep inclines and challenging road conditions.

Racing vehicles, whether on the track or off-road, require lightning-fast gear changes and precise control over power delivery to maximize performance. To meet these demands, racing gearboxes often feature sequential or dual-clutch designs, allowing for seamless shifts without the interruption of power flow. With gear ratios optimized for acceleration and top speed, these gearboxes are the epitome of high-performance engineering.

Industrial Gearboxes

In the realm of manufacturing, construction, and heavy machinery, industrial gearboxes play a pivotal role in powering everything from conveyor belts to cranes. Designed to withstand high loads and operating temperatures, these gearboxes are built to last in the most demanding of environments.

In manufacturing facilities, industrial gearboxes are responsible for driving conveyor systems, robotic arms, and other automated machinery with precision and reliability. With options ranging from helical and spur gears to planetary gear sets, manufacturers can choose the gearbox configuration best suited to their specific production needs.

In construction and mining, heavy machinery relies on industrial gearboxes to provide the torque and power necessary for earthmoving and excavation. Whether it’s a bulldozer pushing tons of dirt or a hydraulic excavator digging deep into the ground, industrial gearboxes ensure that these machines can handle the toughest jobs with ease.

Marine Gearboxes

When it comes to navigating the high seas, marine vessels and boats require specialized gearboxes designed to withstand the harsh conditions of saltwater environments. From pleasure craft to commercial ships, marine gearboxes are essential for controlling propulsion and maneuvering.

In pleasure craft, marine gearboxes provide the necessary reduction in engine speed to drive propellers efficiently while also allowing for forward, reverse, and neutral gear engagement. With options for both inboard and outboard installations, boat owners can choose the gearbox configuration that best suits their vessel’s design and performance requirements.

Commercial ships, on the other hand, rely on marine gearboxes to transmit power from the engines to the propeller shafts, ensuring smooth and reliable propulsion over long distances. These gearboxes are engineered to handle the high torque loads generated by large diesel engines while also providing precise control over thrust and speed.

In summary, the classification of gearboxes by purpose highlights the diverse range of applications and design considerations inherent in gearbox technology. Whether it’s powering vehicles on land, machinery in factories, or vessels at sea, gearboxes play a vital role in keeping our world moving forward.

Performance and Efficiency Considerations

Impact of Gearbox Design on Fuel Economy

Ever wondered how the design of your vehicle’s gearbox affects its fuel efficiency? Well, wonder no more! The gearbox plays a crucial role in determining how efficiently your engine converts fuel into motion. By selecting the right gear ratio for a given speed and load, a well-designed gearbox can help keep the engine operating within its optimal RPM range, where fuel consumption is minimized. This means smoother acceleration, reduced engine strain, and ultimately, fewer trips to the gas station.

Handling Power and Torque in Various Gearbox Types

When it comes to handling power and torque, not all gearboxes are created equal. Different gearbox types are engineered to accommodate varying levels of power output and torque demands. For example, manual transmissions with their robust gear sets and mechanical linkages are well-suited for handling high torque loads, making them a popular choice for towing and heavy-duty applications. On the other hand, continuously variable transmissions (CVTs) offer a more flexible approach to power management, smoothly adjusting the transmission ratio to match the engine’s output, regardless of speed or load. Understanding how different gearbox types handle power and torque is key to selecting the right transmission for your vehicle’s needs.

Noise, Vibration, and Durability Factors

Nobody likes a noisy, shaky gearbox! That’s why manufacturers go to great lengths to design gearboxes that are not only durable but also smooth and quiet in operation. Noise and vibration can be indicative of gearbox wear or misalignment, potentially leading to costly repairs down the road. By using high-quality materials, precision machining techniques, and advanced vibration damping technologies, gearbox manufacturers strive to minimize these unwanted effects, ensuring a comfortable and reliable driving experience for motorists.

Durability is another critical factor to consider when evaluating gearbox performance. Whether it’s enduring the rigors of daily commuting or tackling off-road adventures, gearboxes need to be able to withstand the demands of real-world driving conditions. Proper lubrication, robust gear construction, and rigorous testing protocols all contribute to ensuring that gearboxes are up to the task, delivering years of trouble-free operation.

In summary, when it comes to performance and efficiency considerations, the design of the gearbox plays a central role in determining how well a vehicle performs on the road. From fuel economy and power handling to noise and vibration levels, every aspect of gearbox design is carefully engineered to deliver the best possible driving experience for motorists. By understanding these factors, drivers can make informed decisions when choosing a vehicle and enjoy the benefits of a well-designed gearbox for years to come.

Specialized Gearboxes for Unique Applications

Planetary Gearboxes

Planetary gearboxes, with their compact and efficient design, find extensive utilization in various industries, from robotics to aerospace. But what makes them so special? Unlike traditional gearboxes, which rely on parallel shafts to transmit power, planetary gearboxes feature a central sun gear surrounded by multiple planet gears, all contained within an outer ring gear. This arrangement allows for a high gear ratio in a relatively small package, making planetary gearboxes ideal for applications where space is limited.

Utilizations in Robotics and Aerospace

In the world of robotics, where precision and reliability are paramount, planetary gearboxes play a crucial role in translating the motion of motors into the precise movements of robotic arms and manipulators. With their high torque density and smooth operation, planetary gearboxes enable robots to perform intricate tasks with speed and accuracy, whether it’s assembling electronics or performing surgery.

Similarly, in the aerospace industry, where weight and space constraints are critical considerations, planetary gearboxes are prized for their lightweight construction and compact footprint. From adjusting the flaps on an aircraft’s wings to controlling the movements of satellites in orbit, planetary gearboxes provide the precise motion control needed to keep aerospace systems operating smoothly and safely.

Hybrid Vehicle Transmissions

Hybrid vehicles represent the synergy of electric and internal combustion engines, and specialized gearboxes play a key role in optimizing their performance and efficiency. By seamlessly integrating the power delivery from both sources, hybrid vehicle transmissions enable smooth transitions between electric and gasoline propulsion modes, maximizing fuel economy and reducing emissions.

Synergy of Electric and Internal Combustion Engines

In a hybrid vehicle, the gearbox must be able to handle the unique characteristics of both electric and internal combustion engines. This requires a sophisticated control system that can seamlessly switch between power sources based on driving conditions, such as acceleration, speed, and battery charge level. Whether it’s harnessing the instant torque of an electric motor for swift acceleration or leveraging the long-range capabilities of a gasoline engine for highway cruising, hybrid vehicle transmissions ensure optimal performance across a wide range of driving scenarios.

High-Speed Gearboxes for Wind Turbines

Wind turbines harness the power of the wind to generate electricity, and specialized gearboxes are essential for converting the low-speed rotation of the turbine blades into the high-speed rotation needed to drive the generator. With their robust construction and precise gear ratios, high-speed gearboxes enable wind turbines to operate efficiently and reliably, even in harsh weather conditions.

Addressing Demands of Renewable Energy Systems

As the demand for renewable energy continues to grow, so too does the need for reliable and efficient wind turbine gearboxes. These gearboxes must be able to withstand the constant stress and strain of continuous operation, while also minimizing maintenance requirements and maximizing energy output. By optimizing gear designs, lubrication systems, and materials selection, gearbox manufacturers are helping to drive the transition to a cleaner, more sustainable energy future.

In conclusion, specialized gearboxes play a critical role in a wide range of unique applications, from robotics and aerospace to hybrid vehicles and wind turbines. By leveraging advanced engineering principles and innovative design techniques, gearbox manufacturers are helping to push the boundaries of what’s possible, enabling new technologies and industries to thrive.

Emerging Trends and Future Directions

Advancements in Gearbox Technology

Gearbox technology is continuously evolving, driven by the demand for improved performance, efficiency, and reliability. From innovative materials and manufacturing techniques to advanced computer-aided design (CAD) software, manufacturers are pushing the boundaries of what’s possible in gearbox design. By optimizing gear profiles, reducing friction losses, and enhancing thermal management systems, the latest generation of gearboxes offers unprecedented levels of efficiency and durability.

Incorporation of IoT and Predictive Maintenance

The Internet of Things (IoT) is revolutionizing gearbox maintenance by enabling real-time monitoring of key performance metrics, such as temperature, vibration, and lubricant condition. By collecting and analyzing data from sensors embedded within the gearbox, maintenance teams can identify potential issues before they escalate into costly failures, minimizing downtime and maximizing productivity. Predictive maintenance algorithms leverage machine learning and artificial intelligence to predict when maintenance is needed, allowing for proactive interventions and extending the lifespan of gearbox components.

Sustainable Gearbox Solutions

As sustainability becomes an increasingly important consideration in engineering design, gearbox manufacturers are exploring eco-friendly alternatives to traditional materials and lubricants. From biodegradable lubricants derived from renewable sources to gear materials sourced from recycled or recyclable materials, sustainable gearbox solutions are paving the way towards a greener future. By reducing environmental impact and promoting circular economy principles, these innovations are helping to mitigate the carbon footprint of gearbox manufacturing and operation.

Eco-Friendly Lubricants and Materials

The lubricants and materials used in gearboxes play a critical role in determining their environmental impact. By transitioning to eco-friendly lubricants, such as biodegradable oils or synthetic alternatives with reduced toxicity, gearbox manufacturers can minimize the release of harmful chemicals into the environment while maintaining optimal performance. Similarly, the use of sustainable materials, such as bio-based plastics or composites, can help reduce the carbon footprint of gearbox production and disposal, contributing to a more sustainable supply chain.

Integration with Electric Vehicles

With the rise of electric vehicles (EVs), gearbox manufacturers are adapting their designs to meet the unique requirements of electric drivetrains. Unlike traditional internal combustion engines, electric motors operate over a wider RPM range and deliver instant torque, necessitating gearbox designs optimized for efficiency and durability. By incorporating lightweight materials, compact designs, and advanced cooling systems, gearbox manufacturers are helping to maximize the range and performance of electric vehicles, accelerating the transition to a zero-emission future.

Adapting Gearboxes to the Electric Mobility Revolution

As the automotive industry undergoes a paradigm shift towards electric mobility, gearbox manufacturers are at the forefront of innovation, developing new transmission solutions tailored to the needs of electric vehicles. From single-speed transmissions optimized for city driving to multi-speed gearboxes for high-performance applications, the future of gearbox technology is electric. By embracing electrification and leveraging advancements in motor and battery technology, gearbox manufacturers are playing a crucial role in shaping the future of transportation, one gear at a time.