How to Make a Socket: DIY Electrical Guide

Understanding Socket Basics

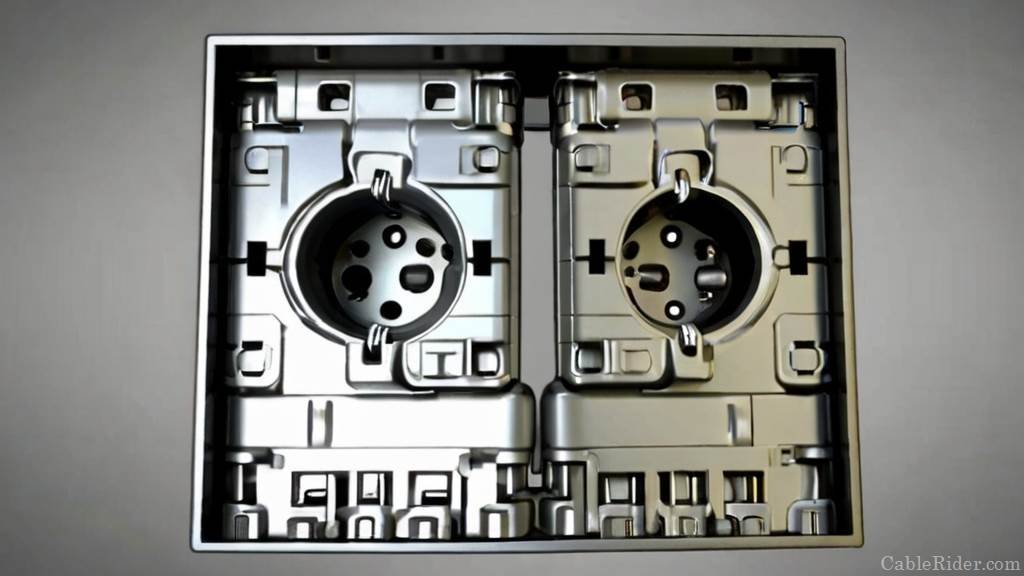

Anatomy of a Socket

Sockets, those humble yet indispensable components of our electrical systems, are more complex than they might seem at first glance. A typical socket consists of several key parts, each playing a crucial role in its function. At its core lies the receptacle, which provides the connection point for electrical plugs. Surrounding the receptacle is the faceplate, often made of durable plastic or metal, designed to protect the inner workings of the socket and provide a tidy appearance. Within the receptacle, there are metal contacts that make contact with the prongs of a plug, allowing electricity to flow safely from the power source to the connected device. Understanding these components is essential for anyone venturing into socket installation or repair.

Contents

ToggleTypes of Sockets

Just as there are various electrical devices, there are also different types of sockets to accommodate their specific requirements. One common differentiator is the number of outlets a socket provides, ranging from single to multiple outlets on a single faceplate. Additionally, sockets can vary based on their configuration, such as standard sockets, which accept typical two-prong or three-prong plugs, and specialized sockets designed for specific applications, such as those used for high-power appliances or audiovisual equipment. Furthermore, sockets can differ in their voltage and current ratings, ensuring compatibility with the devices they will power. Understanding the diverse range of socket types allows individuals to select the appropriate option for their electrical needs.

Importance of Proper Installation

The importance of proper socket installation cannot be overstated, as it directly impacts both safety and functionality. Incorrectly installed sockets pose significant risks, including electrical shock, fire hazards, and damage to connected devices. Proper installation involves several critical steps, including accurate wiring, secure attachment to the wall, and adherence to safety protocols. Moreover, ensuring the socket is compatible with the electrical system’s voltage and current specifications is essential for preventing overloads and potential damage. By prioritizing proper installation procedures, individuals can safeguard their homes and occupants while maximizing the longevity and efficiency of their electrical systems.

Now, let’s delve into the process of preparing for socket installation, ensuring that you have everything you need to proceed safely and effectively.

Preparing for Socket Installation

Assessing Electrical Needs

Before diving into the installation process, it’s crucial to assess your electrical needs to ensure the socket you install can adequately meet them. Ask yourself questions such as:

- How many devices will be connected to this socket?

- What types of devices will be plugged in (e.g., small appliances, electronics)?

- What is the typical power consumption of these devices?

- Are there any specific voltage or current requirements to consider?

By answering these questions, you’ll gain clarity on the type and specifications of the socket needed for your specific application. For instance, if you plan to connect multiple high-power appliances to the same socket, you may require a specialized outlet with higher voltage and current ratings to prevent overloads.

Gathering Necessary Tools and Materials

With your electrical needs identified, it’s time to gather the tools and materials required for the installation process. Here’s a checklist to ensure you have everything you need:

- Sockets: Select the appropriate type and quantity of sockets based on your assessment of electrical needs.

- Wiring: Ensure you have the necessary wiring, such as electrical cables, to connect the socket to the power source.

- Tools: Gather basic tools like screwdrivers, wire cutters, and a voltage tester for safe and efficient installation.

- Faceplates: If your sockets don’t come with integrated faceplates, purchase suitable faceplates to cover the installed sockets.

- Safety Equipment: Don’t forget safety equipment such as gloves and safety goggles to protect yourself during the installation process.

By having all the tools and materials on hand before you start, you’ll streamline the installation process and minimize interruptions or delays.

Safety Precautions

Safety should always be the top priority when working with electricity. Before beginning the installation, take the following safety precautions:

- Turn Off Power: Always turn off the power supply to the area where you’ll be working to avoid the risk of electric shock.

- Use Proper Wiring Techniques: Ensure all wiring connections are secure and properly insulated to prevent electrical hazards.

- Check for Hazards: Before drilling or cutting into walls, check for hidden hazards such as pipes or cables to avoid accidental damage.

- Test Before Touch: Use a voltage tester to confirm that the power is off before touching any wires or components.

- Work with a Partner: If possible, have someone nearby to assist you in case of emergencies or accidents.

By adhering to these safety precautions, you can minimize the risks associated with socket installation and ensure a safe working environment for yourself and others involved.

Now that you’re equipped with the knowledge and resources needed to prepare for socket installation let’s move on to the next step: creating the socket opening.

Creating the Socket Opening

Locating the Ideal Position

Finding the perfect spot for your socket is the first step in creating the opening. But how do you determine the ideal position? Consider these factors:

- Accessibility: Choose a location that is easily accessible and convenient for plugging in devices.

- Functionality: Think about the intended use of the socket. For example, in a kitchen, you might want sockets near countertops for small appliances.

- Aesthetics: Take into account the overall aesthetics of the room. Try to place the socket where it blends seamlessly with the surroundings.

- Safety: Ensure the location is away from water sources and other potential hazards.

By carefully considering these factors, you can pinpoint the optimal position for your socket, maximizing both functionality and safety.

Marking and Cutting the Opening

Once you’ve identified the ideal position, it’s time to mark and cut the opening for the socket. Here’s a step-by-step guide:

- Measure Twice, Cut Once: Use a tape measure to accurately measure the dimensions of the socket box. Double-check your measurements to avoid mistakes.

- Mark the Outline: Using a pencil or marker, trace the outline of the socket box onto the wall. Make sure the outline is level and centered.

- Prepare for Cutting: Put on safety goggles and gloves to protect yourself during the cutting process. If necessary, use a stud finder to locate any studs or obstacles behind the wall.

- Cut the Opening: Carefully cut along the marked outline using a drywall saw or utility knife. Take your time and work slowly to ensure a clean and precise cut.

- Test Fit: Once the opening is cut, test fit the socket box to ensure it fits properly. Make any necessary adjustments to the opening as needed.

By following these steps, you can create a neat and accurate opening for your socket, ready for installation.

Dealing with Obstacles (e.g., Studs, Pipes)

Sometimes, you may encounter obstacles such as studs or pipes when cutting the opening for your socket. Here’s how to deal with them:

- Studs: If you encounter a stud behind the wall, use a stud finder to locate its edges. Then, carefully cut around the stud, ensuring the opening is wide enough to accommodate the socket box.

- Pipes: If there are pipes behind the wall, take extra precautions to avoid damaging them. Use a pipe detector to locate the pipes before cutting, and cut cautiously to prevent accidental punctures.

By taking these precautions and addressing any obstacles with care, you can navigate around potential challenges and successfully create the socket opening without causing damage to your walls or utilities.

Now that you’ve mastered the art of creating the socket opening, let’s move on to the next step: wiring the socket.

Wiring the Socket

Choosing the Right Wiring Method

When it comes to wiring a socket, selecting the appropriate wiring method is essential for ensuring safety and efficiency. But with various options available, how do you choose the right one? Consider the following factors:

- Wire Gauge: Determine the appropriate wire gauge based on the electrical load and distance from the power source. Using the correct gauge prevents overheating and ensures optimal performance.

- Conduit vs. Non-Conduit: Decide whether to run the wiring through conduit or directly behind the wall. Conduit offers added protection but may be more challenging to install, while non-conduit wiring is simpler but may be less durable.

- Location: Consider the location of the socket and any specific requirements, such as moisture resistance for outdoor sockets or fire-rated wiring for sockets near combustible materials.

By carefully evaluating these factors, you can choose the wiring method that best suits your needs and ensures a safe and reliable electrical connection.

Connecting Wires to the Socket

With the wiring method selected, it’s time to connect the wires to the socket. Follow these steps for a successful connection:

- Prepare the Wires: Strip the insulation from the ends of the wires using wire strippers, exposing about half an inch of bare wire.

- Identify Terminals: Identify the terminal screws on the socket, typically labeled “live,” “neutral,” and “ground.” Match the corresponding wires to each terminal.

- Secure the Wires: Loosen the terminal screws, insert the stripped ends of the wires into the appropriate terminals, and tighten the screws securely. Ensure there are no loose strands of wire protruding from the terminals.

- Check Connections: Once all wires are connected, double-check the connections to ensure they are tight and secure. Any loose connections could lead to electrical hazards or malfunctioning sockets.

By following these steps, you can effectively connect the wires to the socket, creating a reliable electrical connection that will power your devices safely.

Ensuring Proper Grounding

Proper grounding is crucial for the safety and functionality of electrical sockets. But what exactly is grounding, and how do you ensure it’s done correctly?

- Definition: Grounding involves connecting the metal components of the socket to the earth or a grounding conductor to prevent the buildup of excess electrical charge and reduce the risk of electric shock.

- Grounding Conductor: Ensure that a dedicated grounding conductor is connected to the grounding terminal of the socket and securely bonded to the grounding system of the building.

- Testing: Use a multimeter or continuity tester to verify proper grounding. A properly grounded socket should show continuity between the grounding terminal and a known ground source.

By prioritizing proper grounding, you can enhance the safety of your electrical system and protect against potential hazards such as electrical shocks and fires.

With the wiring completed and the socket properly grounded, you’re one step closer to enjoying reliable electrical power in your space. Now, let’s move on to the final step: installing the socket.

Installing the Socket

Inserting the Socket into the Opening

With the wiring in place, it’s time to insert the socket into the opening you’ve created. But how do you do it safely and securely? Follow these steps for a smooth installation:

- Positioning: Carefully align the socket with the opening, ensuring it sits flush against the wall.

- Guided Insertion: Gently guide the socket into the opening, taking care not to damage the wires or surrounding wall.

- Check Alignment: Double-check the alignment of the socket to ensure it is level and centered within the opening.

- Press Fit: Once properly positioned, press the socket into place until it sits snugly within the opening.

By following these steps, you can insert the socket into the opening with ease, setting the stage for the next crucial step in the installation process.

Securing the Socket to the Wall

Once the socket is inserted into the opening, the next step is to secure it to the wall to ensure stability and safety. Here’s how to do it effectively:

- Screw Placement: Locate the screw holes on the faceplate of the socket and position it against the wall.

- Drive Screws: Using a screwdriver, drive screws through the screw holes and into the wall, securing the socket in place.

- Even Tightening: Tighten the screws evenly to ensure the socket is securely fastened without any wobbling or movement.

- Test Stability: After securing the socket, give it a gentle tug to ensure it is firmly attached to the wall.

By properly securing the socket to the wall, you can prevent it from coming loose or falling out, providing a safe and reliable electrical connection for your devices.

Testing for Stability

Before considering the installation complete, it’s essential to test the stability of the socket to ensure it can withstand regular use. Here’s how to do it:

- Physical Inspection: Visually inspect the socket to ensure it is flush against the wall and there are no visible gaps or gaps.

- Wiggle Test: Gently wiggle the socket to check for any looseness or movement. A stable socket should feel firmly anchored to the wall.

- Plug Test: Insert a plug into the socket and gently tug on the cord to ensure the socket remains securely in place.

- Functional Test: Turn on the power and test the socket with a small device to ensure it is functioning correctly.

By conducting these tests, you can verify the stability of the socket and address any issues before finalizing the installation.

With the socket securely installed and tested for stability, you’re one step closer to enjoying reliable electrical power in your space. Now, it’s time to move on to the final step: screwing the socket into place.

Screwing the Socket into Place

Selecting the Correct Screws

Choosing the right screws for securing your socket is crucial for a successful installation. But with various options available, how do you make the right choice? Consider the following factors:

- Length: Select screws that are long enough to securely fasten the socket to the wall without protruding too far.

- Thread Type: Opt for screws with threads designed for use with the material of your wall, whether it’s drywall, plaster, or wood.

- Head Type: Choose screws with a head type that matches the screwdriver you’ll be using for installation, such as Phillips or flathead.

- Material: Ensure the screws are made of durable material that can withstand the weight and pressure exerted on the socket.

By considering these factors, you can confidently select the correct screws for securing your socket, setting the stage for a successful installation.

Aligning the Socket with the Opening

Proper alignment of the socket with the opening is essential for a neat and professional-looking installation. Here’s how to ensure alignment:

- Visual Inspection: Before securing the socket, visually inspect its position relative to the opening to ensure it is centered and level.

- Adjustment: If necessary, make any minor adjustments to the position of the socket to ensure it aligns perfectly with the opening.

- Double-Check: Take a step back and double-check the alignment from different angles to ensure it meets your aesthetic standards.

- Verify Fit: Test fit the faceplate over the socket to ensure it covers the opening completely and sits flush against the wall.

By taking the time to align the socket properly with the opening, you can achieve a professional-looking installation that enhances the overall appearance of your space.

Using Proper Techniques for Tightening

Proper tightening techniques are essential for ensuring the screws securely fasten the socket to the wall without causing damage. Here are some tips for tightening screws effectively:

- Steady Pressure: Apply steady pressure to the screwdriver while turning it to prevent slipping and ensure the screw penetrates the wall material evenly.

- Avoid Over-Tightening: Tighten the screws until they are snug against the wall, but avoid over-tightening, which can strip the threads or damage the wall material.

- Alternate Tightening: Tighten the screws in a diagonal pattern, alternating between screws, to ensure even distribution of pressure and prevent warping or misalignment.

- Final Check: After tightening all screws, give the socket a gentle tug to ensure it is securely fastened to the wall.

By using proper tightening techniques, you can ensure the screws hold the socket firmly in place, providing a stable and reliable electrical connection for your devices.

With the socket securely screwed into place, you’ve completed the installation process and are one step closer to enjoying the convenience of accessible power in your space. Now, it’s time to move on to the final step: testing the socket for stability and functionality.

Finalizing the Installation

Concealing Wires and Screws

Once the socket is securely installed, the next step is to conceal any exposed wires and screws to create a clean and polished appearance. Here’s how to do it effectively:

- Wire Management: Use cable clips or channels to neatly organize and route any exposed wires, keeping them out of sight and reducing the risk of tripping hazards.

- Concealing Screws: If the screws used to secure the socket are visible, consider using screw caps or covers to conceal them and create a seamless finish.

- Painting: If necessary, touch up any paint around the socket opening to match the surrounding wall, further enhancing the overall aesthetic.

By concealing wires and screws, you can achieve a professional-looking installation that enhances the appearance of your space while maintaining safety and functionality.

Inspecting for Flaws or Hazards

Before considering the installation complete, it’s essential to conduct a thorough inspection for any flaws or hazards that may compromise safety or performance. Here’s what to look for:

- Loose Connections: Check all wiring connections to ensure they are tight and secure, reducing the risk of electrical hazards or malfunction.

- Visible Damage: Inspect the socket and surrounding area for any signs of damage, such as cracks, dents, or exposed wires, that may pose safety risks.

- Fire Hazards: Look for any potential fire hazards, such as overheating sockets or flammable materials in close proximity, and address them promptly.

- Water Damage: If installing outdoor sockets or sockets in damp areas, check for signs of water damage or corrosion that may affect performance.

By conducting a thorough inspection, you can identify and address any potential issues before they escalate into safety hazards or costly repairs.

Tips for Maintenance and Troubleshooting

To ensure your newly installed socket continues to function reliably, here are some tips for ongoing maintenance and troubleshooting:

- Regular Inspections: Periodically inspect the socket for signs of wear or damage, such as loose connections or discoloration, and address any issues promptly.

- Cleaning: Keep the socket and surrounding area clean and free of dust and debris to prevent overheating and maintain optimal performance.

- Testing: Test the socket periodically by plugging in devices and ensuring they receive power consistently. If you encounter any issues, troubleshoot the problem promptly to prevent further damage.

- Professional Assistance: If you’re unsure how to address a maintenance issue or encounter persistent problems with the socket, don’t hesitate to seek assistance from a qualified electrician.

By following these maintenance tips and knowing how to troubleshoot common issues, you can ensure your socket remains safe, reliable, and functional for years to come.

With the installation finalized and any necessary maintenance tasks completed, you can now enjoy the convenience of accessible power in your space, knowing that your socket is installed safely and securely. Now, it’s time to sit back, relax, and enjoy the benefits of your hard work.