Unlocking the Mysteries: Phase Blue or Brown

Understanding the Significance of Phase Colors in Electrical Wiring

Importance of Proper Wiring Identification

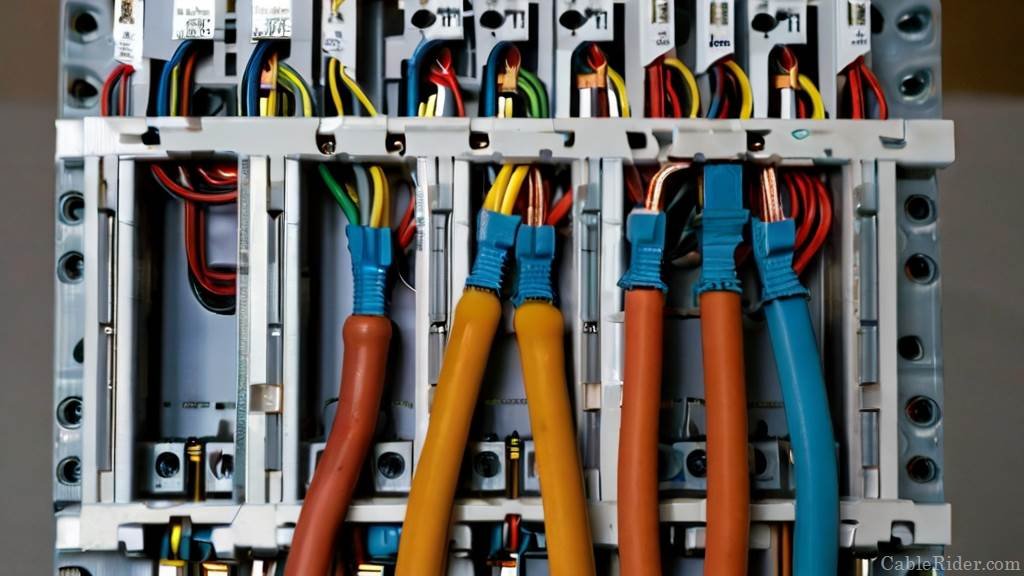

In the intricate web of electrical systems, proper identification of wiring is akin to deciphering the language of safety. Imagine a scenario where every wire wore the same coat of color – chaos would reign supreme! It’s not just about convenience, it’s about averting disasters waiting to strike. Identifying wires by their distinct colors isn’t just a convention, it’s a lifeline.

Contents

ToggleWhy do electrical wires come in different colors?

The color-coded system isn’t arbitrary, it’s a carefully crafted mechanism born out of necessity. Picture the perplexity of an electrician if every wire in a circuit sported the same hue. Chaos would ensue, rendering even the most seasoned professional helpless. The diversity in colors acts as a beacon, guiding experts through the labyrinth of circuits with precision.

How does proper identification prevent mishaps?

Think of proper wiring identification as the guardian angel of electrical safety. When wires are correctly distinguished, the likelihood of connecting them erroneously plummets. This means fewer chances of short circuits, electrical fires, or worse, electrocution. It’s the difference between a well-lit path and a dark alley fraught with danger.

Safety Implications of Incorrect Wiring

In the world of electrical engineering, the consequences of incorrect wiring are dire – and sometimes, fatal. A simple mix-up of wires can spell disaster, turning a mundane task into a perilous gamble. Safety isn’t just about wearing gloves or goggles, it’s about understanding the language of wires and speaking it fluently.

What are the risks associated with incorrect wiring?

Picture this: a home wired haphazardly, with no regard for color codes. In such a scenario, every flip of the switch becomes a game of chance, with potentially catastrophic outcomes. From appliances malfunctioning to circuits overloading, the repercussions of incorrect wiring reverberate throughout the entire electrical network.

How can proper wiring save lives?

Proper wiring isn’t just about aesthetics or functionality, it’s about preserving precious lives. When wires are correctly identified and connected, the chances of accidents plummet. It’s like fitting together the pieces of a puzzle – each wire has its place, and when they align, the result is a picture-perfect landscape of safety.

Historical Evolution of Wiring Standards

The journey of wiring standards is a tapestry woven with threads of innovation, necessity, and occasional mishaps. From humble beginnings to the complex network of regulations we see today, the evolution of wiring standards is a testament to human ingenuity and the relentless pursuit of safety.

How did early civilizations handle electrical wiring?

Long before the advent of modern electrical systems, early civilizations grappled with the concept of wiring. From rudimentary conductors to primitive circuits, the journey towards understanding electricity was fraught with trial and error. Yet, out of this experimentation emerged the seeds of modern wiring standards, sowing the foundation for generations to come.

What spurred the need for standardized wiring practices?

As technology advanced and electricity became more ubiquitous, the need for standardized wiring practices became glaringly apparent. No longer could electrical systems operate in a haphazard manner, precision was paramount. Thus, began the quest for a universal language of wiring – one that transcended borders and bridged the gap between safety and functionality.

Deciphering the Meaning Behind Blue Wires in Electrical Sockets

Origins and Standards of Blue Phase Wiring

In the grand tapestry of electrical engineering, every color has its tale to tell, and blue is no exception. But where did this enigmatic hue come from, and why does it hold such significance in the realm of electrical wiring?

The Story Behind Blue Phase Wiring

The origins of blue phase wiring trace back to the dawn of standardized electrical systems. As the demand for electricity surged, the need for a universal language of wiring became apparent. Thus, emerged the color-coded system, with each hue assigned a specific role in the electrical symphony.

Blue, with its calm and tranquil demeanor, was deemed the perfect candidate for representing phase wiring. Its distinctiveness made it easily recognizable amidst the tangle of wires, ensuring clarity and coherence in electrical installations.

Standards and Regulations

Over time, blue phase wiring became synonymous with safety and reliability, thanks to stringent standards and regulations governing its use. From international codes to regional directives, the blue wire has stood the test of time, earning its rightful place in the pantheon of electrical standards.

Common Applications of Blue Wires in Different Regions

As the world grows more interconnected, the language of wiring transcends borders, with blue wires weaving their way into electrical installations across the globe. But how does this versatile hue manifest itself in various regions, and what are its common applications?

Blue Wires in Residential Settings

In many countries, blue wires are the go-to choice for phase wiring in residential settings. From powering lighting fixtures to energizing appliances, these azure conduits play a pivotal role in keeping homes illuminated and functional.

Industrial and Commercial Applications

Beyond the confines of residential dwellings, blue wires find ample employment in industrial and commercial settings. Whether it’s powering machinery on the factory floor or lighting up office spaces, these stalwart wires are the backbone of modern infrastructure.

Specialized Uses

In certain specialized applications, blue wires shine brightest, showcasing their adaptability and versatility. From telecommunications to automotive electronics, these azure conduits find their way into a myriad of niche applications, proving that their utility knows no bounds.

Safety Measures Associated with Blue Phase Wiring

While blue wires may exude an aura of reliability, ensuring their safe deployment requires adherence to a strict set of guidelines and precautions. After all, safety is paramount when dealing with the currents that course through these azure lifelines.

Proper Installation Techniques

Proper installation is the first line of defense against electrical hazards. From ensuring correct terminations to securely fastening wires, every step must be taken with precision and care to prevent potential mishaps down the line.

Regular Maintenance and Inspection

Like any component of an electrical system, blue wires require regular maintenance and inspection to ensure their continued reliability. From checking for signs of wear and tear to verifying connections, proactive measures can nip potential problems in the bud before they escalate.

Awareness and Education

Ultimately, safety begins with awareness and education. Ensuring that those working with electrical systems understand the significance of blue phase wiring and the precautions necessary for its safe deployment is key to preventing accidents and promoting a culture of safety.

Unveiling the Role of Brown Wires in Electrical Systems

Origins and Standards of Brown Phase Wiring

Have you ever wondered about the origins of the unassuming brown wire that quietly powers our homes and workplaces? Let’s peel back the layers and uncover the rich history and standards that govern the realm of brown phase wiring.

The Birth of Brown Wiring

Brown phase wiring emerged from the need for a standardized system that would streamline electrical installations and ensure safety and reliability. Its earthy hue, reminiscent of the soil beneath our feet, became synonymous with stability and grounding, laying the foundation for a robust electrical infrastructure.

Compliance and Regulations

From the corridors of power to the humble abodes of everyday citizens, brown wiring adheres to a strict set of standards and regulations. International codes and regional directives mandate its use in specific applications, ensuring uniformity and compatibility across diverse electrical systems.

Applications and Compatibility of Brown Wires in Various Systems

Brown wires may fly under the radar, but their versatility and compatibility make them indispensable in a myriad of electrical systems. From household appliances to industrial machinery, these unassuming conduits quietly power our world.

Residential Applications

In the cozy confines of our homes, brown wires play a crucial role in powering lighting circuits and connecting appliances. Whether it’s flipping a switch to illuminate a room or firing up the oven for a culinary adventure, brown wires work tirelessly behind the scenes to keep the lights on and the gadgets running.

Industrial and Commercial Uses

Beyond the confines of residential settings, brown wires find ample employment in industrial and commercial applications. From powering heavy machinery on the factory floor to energizing complex HVAC systems in office buildings, these stalwart conduits are the backbone of modern infrastructure.

Compatibility with Modern Technology

In an era defined by technological innovation, brown wires seamlessly integrate with the latest advancements in electronics and automation. From smart home devices to renewable energy systems, these versatile conduits adapt to the ever-evolving landscape of modern technology, ensuring compatibility and reliability.

Safety Considerations with Brown Phase Wiring

While brown wires may blend seamlessly into the backdrop of our electrical systems, ensuring their safe deployment requires vigilant attention to safety considerations and best practices.

Proper Installation Techniques

Proper installation is paramount when working with brown phase wiring. From securely fastening connections to ensuring adequate grounding, every step must be taken with precision and care to mitigate the risk of electrical hazards.

Regular Maintenance and Inspection

Like any component of an electrical system, brown wires require regular maintenance and inspection to ensure their continued reliability. From checking for signs of wear and tear to verifying connections, proactive measures can help identify and address potential issues before they escalate.

Awareness and Education

Ultimately, safety begins with awareness and education. Ensuring that those working with electrical systems understand the significance of brown phase wiring and the precautions necessary for its safe deployment is essential for preventing accidents and promoting a culture of safety.

Comparative Analysis: Blue vs. Brown Wiring in Socket Installations

Contrasting Characteristics of Blue and Brown Wiring

When it comes to electrical wiring, blue and brown are like yin and yang – each with its distinct personality and purpose. But what sets these two hues apart, and how do they stack up against each other in the realm of socket installations?

Blue Wiring: The Essence of Phase Identification

Blue wiring, with its serene hue reminiscent of a clear summer sky, is the quintessential symbol of phase identification in electrical systems. Its primary role is to carry current to the load, illuminating bulbs and powering appliances with ease. As the cornerstone of phase wiring, blue wires serve as beacons of clarity in the intricate web of electrical installations.

Brown Wiring: The Grounding Guardian

In contrast, brown wiring exudes an earthy warmth, embodying the grounding principles that underpin electrical safety. Its role is to provide a path for fault currents, ensuring that stray electricity is safely diverted away from sensitive circuits and equipment. Like a steadfast guardian, brown wires stand ready to protect against electrical mishaps, grounding us in a sea of currents.

Advantages and Disadvantages of Each Wiring Color

While blue and brown wires share a common goal of powering our electrical systems, they each bring their own set of advantages and disadvantages to the table. Understanding these nuances is key to making informed decisions in socket installations.

Blue Wiring: Advantages

- Clear Identification: Blue wiring serves as a visual cue for phase identification, making it easy for electricians to distinguish between live and neutral conductors.

- Universal Standardization: In many regions, blue wiring follows standardized color codes, promoting consistency and interoperability across diverse electrical systems.

- Versatile Applications: From residential homes to industrial complexes, blue wiring finds widespread use in a variety of applications, thanks to its versatility and reliability.

Blue Wiring: Disadvantages

- Limited Functionality: While blue wiring excels at phase identification, it lacks the grounding capabilities of its brown counterpart, limiting its utility in certain scenarios.

- Potential Confusion: In installations where multiple blue wires are present, there is a risk of confusion, leading to incorrect connections and safety hazards.

Brown Wiring: Advantages

- Effective Grounding: Brown wiring’s primary advantage lies in its grounding capabilities, providing a vital path for fault currents to dissipate harmlessly.

- Enhanced Safety: By redirecting stray electricity away from sensitive circuits, brown wiring helps prevent electrical shocks, fires, and equipment damage.

- Reliable Performance: Brown wiring’s simple yet robust design ensures consistent performance in a wide range of environments, from residential to industrial settings.

Brown Wiring: Disadvantages

- Less Conspicuous: Unlike blue wiring, which serves as a visual indicator of phase, brown wiring may be less conspicuous, posing challenges for identification in complex installations.

- Non-Standardized Color Codes: In some regions, brown wiring may not adhere to standardized color codes, leading to potential confusion and compatibility issues.

Practical Scenarios for Utilizing Blue and Brown Wires

In the intricate dance of socket installations, knowing when to deploy blue and brown wires is crucial for ensuring safety, reliability, and compliance with regulatory standards. Let’s explore some practical scenarios where each wiring color shines brightest.

Utilizing Blue Wiring

- Residential Lighting Circuits: Blue wiring is ideal for powering lighting circuits in residential settings, where clear phase identification is paramount for safety and functionality.

- Appliance Connections: From kitchen appliances to entertainment systems, blue wiring provides a reliable conduit for delivering power to a variety of household devices.

- Industrial Machinery: In industrial environments, blue wiring finds ample use in powering machinery and equipment, thanks to its robust construction and universal standardization.

Utilizing Brown Wiring

- Grounding Systems: Brown wiring is indispensable for establishing grounding systems in electrical installations, safeguarding against electrical shocks, fires, and equipment damage.

- Sensitive Electronics: In environments where sensitive electronics are present, such as data centers and medical facilities, brown wiring ensures reliable protection against stray currents and electromagnetic interference.

- Outdoor Installations: When installing electrical systems in outdoor or wet environments, brown wiring provides an essential layer of protection against moisture and environmental hazards.

The Intricacies of Socket Wiring Color Codes

Overview of Standard Wiring Color Codes

In the labyrinth of electrical installations, wiring color codes serve as the guiding stars, illuminating the path to safety and functionality. But what do these hues signify, and how do they dictate the flow of electricity in socket configurations?

Decoding the Rainbow: Understanding Wiring Color Codes

Wiring color codes vary from region to region, but they typically adhere to a standardized system designed to facilitate clarity and consistency in electrical installations. From the serene blue of phase wiring to the grounding guardian brown, each hue plays a vital role in the symphony of electricity, ensuring that power flows smoothly and safely through the circuits.

Common Wiring Color Codes

- Blue: Often designated for phase wiring, carrying current to the load.

- Brown: Primarily used for line conductors, providing power to electrical devices.

- Green/Yellow: Reserved for grounding conductors, safeguarding against electrical hazards.

- Black: Typically employed for neutral conductors, completing the circuit and returning current to the source.

Interpretation of Color Codes for Different Socket Configurations

Socket configurations come in all shapes and sizes, from residential outlets to industrial power hubs. But how do wiring color codes translate across these diverse settings, and what do they signify for the end user?

Residential Socket Configurations

In residential settings, socket configurations typically adhere to standardized color codes, with blue wires denoting phase conductors, brown wires serving as line conductors, and green/yellow wires fulfilling grounding duties. This uniformity promotes ease of installation and ensures compatibility with a wide range of appliances and devices.

Industrial Power Hubs

In contrast, industrial power hubs may feature more complex socket configurations, necessitating a nuanced understanding of wiring color codes. Here, blue wires may still signify phase conductors, but additional hues such as red or orange may come into play, indicating specialized circuits or higher voltage applications. Adhering to these color standards is essential for maintaining safety and preventing electrical mishaps in industrial environments.

Importance of Adhering to Wiring Color Standards

In the world of electrical engineering, consistency is key. Adhering to wiring color standards isn’t just a matter of convention, it’s a matter of safety, reliability, and regulatory compliance. But why is it so crucial to color within the lines when it comes to socket wiring?

Safety First: Mitigating Electrical Hazards

Wiring color standards serve as a visual roadmap for electricians, guiding them through the maze of circuits with confidence and clarity. By adhering to these standards, the risk of incorrect connections and electrical hazards is greatly reduced, ensuring the safety of both personnel and property.

Facilitating Maintenance and Troubleshooting

In the event of a malfunction or maintenance task, proper adherence to wiring color standards streamlines troubleshooting efforts, allowing technicians to quickly identify and address issues without guesswork or confusion. This not only minimizes downtime but also promotes efficiency and productivity in electrical maintenance operations.

Regulatory Compliance and Liability Mitigation

From local building codes to international standards, regulatory compliance is a non-negotiable aspect of electrical installations. Adhering to wiring color standards not only ensures compliance with applicable regulations but also mitigates liability in the event of accidents or incidents arising from non-compliance. In the eyes of the law, ignorance is not bliss – it’s a liability waiting to happen.

In essence, the intricacies of socket wiring color codes aren’t just a matter of semantics, they’re a cornerstone of electrical safety, reliability, and regulatory compliance. By understanding and adhering to these standards, electricians and end users alike can navigate the currents of electrical installations with confidence and peace of mind.

Troubleshooting and Maintenance Tips for Socket Wiring

Identifying Faults Based on Wire Colors

When the lights flicker and the outlets go silent, it’s easy to feel powerless in the face of electrical faults. But fear not, for understanding wire colors can be your guiding light in troubleshooting socket wiring issues.

Decoding the Language of Colors

Each wire color in a socket serves a distinct purpose, and understanding their roles is key to identifying faults. Blue wires typically carry current to the load, while brown wires provide power to devices. If these wires are frayed, discolored, or improperly connected, it could spell trouble for your electrical system.

Using Visual Cues for Diagnosis

Visual inspection is your first line of defense when troubleshooting socket wiring. Look for signs of wear and tear, such as exposed wires or burn marks. Additionally, pay close attention to the color of the wires – any deviations from the standard hues could indicate a fault that requires further investigation.

Precautionary Measures for Handling Electrical Socket Wiring

Handling electrical socket wiring requires a delicate balance of caution and confidence. From avoiding shocks to preventing fires, taking precautionary measures can mean the difference between a successful repair and a catastrophic failure.

Safety Gear: Your First Line of Defense

Before diving into socket wiring, don’t forget to gear up with the proper safety equipment. Insulated gloves, safety goggles, and non-conductive footwear are essential for protecting yourself against electrical hazards. Remember, it’s better to be safe than sorry!

Power Off, Safety On

When working on socket wiring, always start by shutting off the power at the circuit breaker. This simple yet crucial step prevents accidental shocks and ensures your safety while handling live wires. Additionally, use a voltage tester to double-check that the circuit is truly de-energized before proceeding.

Mindful Manipulation of Wires

As you work with socket wiring, handle the wires with care to avoid damaging them or causing accidental shorts. Use insulated tools whenever possible, and avoid bending wires excessively, as this can weaken the insulation and increase the risk of electrical faults down the line.

Routine Maintenance Practices to Ensure Wiring Integrity

Like any other component of your home, socket wiring requires regular maintenance to ensure its continued reliability and safety. By incorporating routine maintenance practices into your schedule, you can nip potential issues in the bud before they escalate into major problems.

Periodic Inspections: A Stitch in Time

Schedule regular inspections of your socket wiring to check for signs of wear and tear. Look for loose connections, damaged insulation, or any other abnormalities that could indicate impending failure. By catching issues early, you can address them proactively and prevent costly repairs down the line.

Cleanliness is Key

Dust and debris can accumulate around socket wiring over time, increasing the risk of overheating and electrical fires. Periodically clean the area around your sockets with a soft brush or compressed air to keep them free from obstructions and ensure optimal airflow for heat dissipation.

Professional Maintenance Checks

In addition to DIY inspections, consider hiring a qualified electrician for periodic maintenance checks of your socket wiring. A trained professional can identify potential issues that may not be immediately apparent to the untrained eye, providing you with peace of mind and ensuring the continued safety and integrity of your electrical system.

Emerging Trends and Innovations in Electrical Wiring

Technological Advances Impacting Wiring Standards

The landscape of electrical wiring is evolving at a breakneck pace, driven by technological advancements that push the boundaries of innovation. From smart homes to sustainable energy solutions, these emerging trends are reshaping the way we think about wiring standards.

Integration of Smart Technologies

In the era of the Internet of Things (IoT), smart technologies are revolutionizing the way we interact with our electrical systems. Wi-Fi-enabled outlets, smart switches, and intelligent circuit breakers are becoming increasingly prevalent, offering homeowners unprecedented control and automation over their electrical infrastructure. These innovations not only enhance convenience but also improve energy efficiency and promote safety through real-time monitoring and remote access capabilities.

Adoption of Wireless Power Transfer

Wireless power transfer (WPT) is emerging as a game-changer in the world of electrical wiring, offering a convenient and efficient alternative to traditional wired connections. With advancements in resonant coupling and magnetic induction technologies, WPT systems can wirelessly transmit power over short distances, eliminating the need for cumbersome cables and connectors. From charging smartphones to powering electric vehicles, the potential applications of WPT are vast, promising a future where wires are relegated to the annals of history.

Sustainable Practices in Electrical Wiring Design

As concerns about climate change and environmental sustainability continue to escalate, the demand for eco-friendly electrical solutions is on the rise. From renewable energy integration to energy-efficient lighting, sustainable practices are driving innovation in electrical wiring design, paving the way for a greener and more resilient future.

Embracing Renewable Energy Sources

The shift towards renewable energy sources, such as solar and wind power, is reshaping the way we generate and distribute electricity. In addition to reducing reliance on fossil fuels, renewable energy integration presents unique challenges and opportunities for electrical wiring design. Smart grid technologies, microgrid systems, and energy storage solutions are being developed to accommodate fluctuating renewable energy inputs and optimize electrical distribution networks for maximum efficiency and reliability.

Energy-Efficient Lighting Solutions

Lighting accounts for a significant portion of energy consumption in buildings, making it a prime target for energy efficiency improvements. LED lighting technology has emerged as a frontrunner in the quest for energy-efficient illumination, offering superior performance and longevity compared to traditional incandescent and fluorescent bulbs. By incorporating LED lighting into electrical wiring design, homeowners and businesses can significantly reduce energy costs and environmental impact while enjoying bright, high-quality illumination.

Future Outlook: Evolution of Socket Wiring Standards

As we peer into the crystal ball of socket wiring standards, the future appears bright with promise and possibility. From enhanced safety features to seamless integration with emerging technologies, the evolution of socket wiring standards is poised to revolutionize the way we power our homes and workplaces.

Enhanced Safety Features

In an age where safety is paramount, socket wiring standards are expected to evolve to incorporate advanced safety features and fail-safe mechanisms. Ground-fault circuit interrupters (GFCIs), arc-fault circuit interrupters (AFCIs), and residual-current devices (RCDs) are becoming standard components of modern electrical installations, providing enhanced protection against electrical shocks, fires, and other hazards.

Integration with Smart Grid Technologies

As smart grid technologies continue to mature, socket wiring standards will likely evolve to seamlessly integrate with these intelligent energy distribution networks. Smart meters, energy monitoring systems, and demand response mechanisms will enable real-time communication between electrical devices and the grid, optimizing energy usage, reducing costs, and enhancing reliability.

Embrace of Modular and Flexible Designs

The days of rigid, one-size-fits-all electrical wiring solutions are numbered. Socket wiring standards of the future are expected to embrace modular and flexible designs, allowing for easy customization and scalability to meet the unique needs of individual users and applications. Plug-and-play components, interchangeable modules, and expandable systems will empower homeowners and businesses to adapt their electrical infrastructure to evolving technologies and changing lifestyles with ease.

In conclusion, the future of socket wiring is bright with innovation and possibility. From smart technologies to sustainable practices, the evolving landscape of electrical wiring promises to usher in a new era of safety, efficiency, and convenience for homes and businesses alike.