Pinout RJ45 Socket: Mastering Network Connectivity

Understanding RJ45 Socket Pinout

What is RJ45?

RJ45, short for “Registered Jack 45,” is a type of connector commonly used for networking. It’s a standardized physical interface for connecting Ethernet cables to network devices such as computers, routers, and switches. With its modular design and widespread adoption, RJ45 connectors have become the de facto standard for Ethernet connectivity in both residential and commercial environments.

Contents

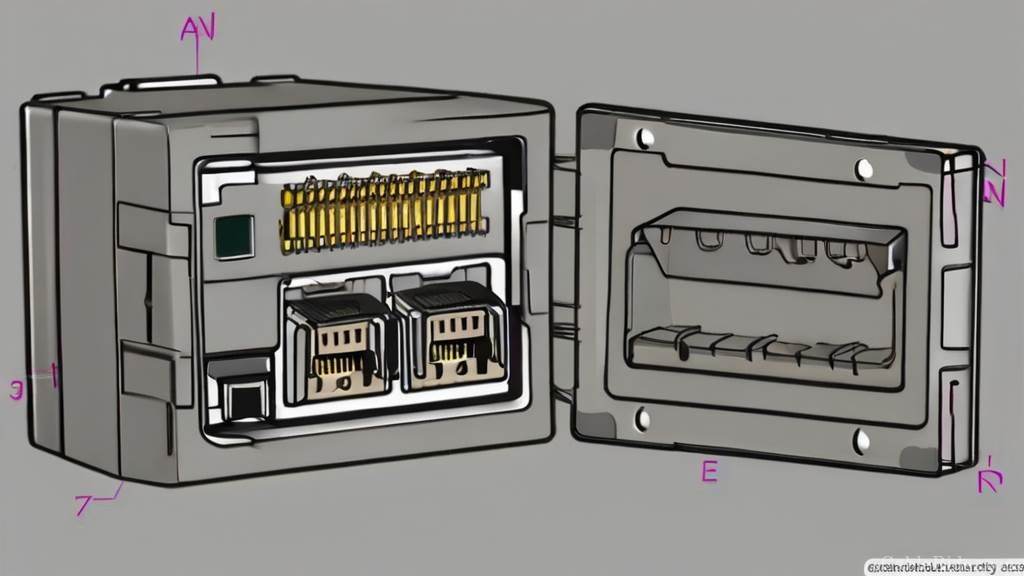

ToggleAnatomy of an RJ45 Socket

An RJ45 socket consists of eight metal pins arranged in a specific configuration within a plastic housing. Each pin serves a distinct purpose in transmitting data across the network. These pins are organized into four pairs, with each pair representing a different color code according to industry standards. Proper alignment of the wires to the pins is crucial for ensuring reliable data transmission.

Importance of Pinout in Networking

The pinout of an RJ45 socket refers to the arrangement of wires within the connector, determining how data signals are transmitted and received. It plays a critical role in maintaining compatibility and ensuring interoperability between network devices. A standardized pinout configuration ensures that Ethernet cables can be easily connected and recognized by different networking equipment, regardless of the manufacturer.

In networking, consistency is key. A deviation from the standard pinout can lead to connectivity issues, signal degradation, or even network failure. Imagine trying to decipher a message when the alphabet is rearranged – it would result in confusion and misunderstanding. Similarly, a misaligned pinout disrupts the orderly flow of data packets, impeding communication between devices.

By adhering to established pinout standards, network administrators can simplify troubleshooting procedures and streamline the deployment of network infrastructure. Whether setting up a small home network or managing a large-scale enterprise environment, maintaining consistency in pinout configurations ensures smooth and efficient operation.

Furthermore, understanding the pinout layout enables technicians to perform tasks such as cable termination and crimping with precision. Each wire serves a specific function in transmitting data, carrying signals for transmission, reception, and power delivery. By following the correct pinout diagram, technicians can ensure that cables are terminated correctly, minimizing the risk of signal interference and ensuring optimal network performance.

In summary, the pinout of an RJ45 socket is a fundamental aspect of networking infrastructure. It dictates how data signals are transmitted between devices and plays a crucial role in maintaining compatibility and reliability. By adhering to standardized pinout configurations, network administrators can ensure seamless connectivity and efficient operation of their networks.

Exploring RJ45 Socket Crimping

The Basics of Crimping

Crimping RJ45 sockets is a fundamental skill for anyone involved in network installation and maintenance. It’s the process of attaching an RJ45 connector to the end of an Ethernet cable, allowing it to be plugged into a network device such as a computer or router. Understanding the basics of crimping is essential for ensuring reliable network connections.

Crimping involves securely attaching the connector to the cable by compressing small metal tabs within the connector onto the individual wires inside the cable. This creates a strong physical and electrical connection, enabling data to be transmitted between devices.

To start crimping, you’ll need to strip away the outer jacket of the Ethernet cable to expose the inner wires. Once exposed, the wires are carefully arranged according to the desired pinout configuration, ensuring each wire is inserted into the correct slot within the connector. With the wires in place, a crimping tool is used to compress the connector, securing it firmly onto the wires and completing the connection.

Tools Required for Crimping RJ45 Sockets

To successfully crimp RJ45 sockets, you’ll need the right tools for the job. Here’s a list of essential tools:

-

Crimping Tool: This specialized tool is designed specifically for crimping RJ45 connectors onto Ethernet cables. It features a built-in wire cutter and stripper, as well as a mechanism for securely compressing the connector onto the wires.

-

Ethernet Cable Stripper: A dedicated cable stripper is used to remove the outer jacket of the Ethernet cable without damaging the inner wires. This ensures a clean and precise cut, facilitating easier crimping.

-

Wire Cutter: While some crimping tools include a built-in wire cutter, having a separate wire cutter on hand can be useful for trimming excess wire length before crimping.

-

RJ45 Connectors: High-quality RJ45 connectors are essential for creating reliable network connections. Make sure to use connectors that are compatible with the gauge of your Ethernet cable and suitable for the desired network speed.

-

Ethernet Cable Tester: While not strictly necessary for crimping, an Ethernet cable tester can be invaluable for verifying the integrity of your crimped connections. It allows you to quickly identify any wiring errors or faults, ensuring optimal network performance.

Safety Measures During Crimping

While crimping RJ45 sockets is a relatively straightforward process, it’s important to prioritize safety to avoid accidents or damage to equipment. Here are some safety measures to keep in mind:

-

Wear Safety Glasses: When using tools such as crimping tools and wire cutters, wear safety glasses to protect your eyes from any flying debris or sharp edges.

-

Handle Tools Properly: Always use tools as intended and handle them with care to prevent injury. Avoid applying excessive force when crimping connectors, as this could damage the tool or result in an incomplete connection.

-

Work in a Well-Ventilated Area: Crimping can generate small metal fragments or dust, so it’s best to work in a well-ventilated area to avoid inhaling any particles.

By following these safety measures and using the right tools, you can confidently crimp RJ45 sockets with precision and efficiency, ensuring robust network connections for your projects.

Step-by-Step Guide on How to Crimp RJ45 Sockets

Preparing the Cable

Before you can begin crimping RJ45 sockets onto Ethernet cables, it’s essential to prepare the cable properly. Follow these steps to ensure a clean and successful crimping process:

-

Measure and Cut: Start by measuring the length of the cable you need and using wire cutters to trim it to size. Make sure to leave a little extra length to account for any mistakes or adjustments.

-

Untwist the Pairs: Gently untwist the twisted pairs of wires within the cable, being careful not to damage or kink them. Straightening the wires will make it easier to arrange them later during the crimping process.

-

Check for Damage: Inspect the cable for any signs of damage, such as cuts or nicks in the outer jacket. If you encounter any damaged sections, trim them away with wire cutters to ensure a clean connection.

Stripping the Cable Sheath

Stripping the outer jacket of the Ethernet cable is the next step in preparing it for crimping. Here’s how to do it properly:

-

Use a Cable Stripper: Select a cable stripper appropriate for the gauge of your Ethernet cable and adjust it to the correct setting. Place the cable into the stripper, ensuring that it’s held securely in place.

-

Rotate and Score: Gently rotate the cable stripper around the outer jacket of the cable, applying light pressure to score the jacket without cutting into the inner wires. Repeat this process until you’ve scored the entire circumference of the jacket.

-

Remove the Jacket: With the outer jacket scored, carefully pull it away from the inner wires to remove it completely. Be cautious not to nick or damage the inner wires during this process, as it could affect the integrity of the connection.

Arranging Wires According to Pinout

Properly arranging the wires according to the desired pinout configuration is crucial for a successful crimp. Follow these steps to ensure correct alignment:

-

Refer to Pinout Diagram: Consult a pinout diagram to determine the correct order of wires for your specific application. Pinout diagrams typically indicate the color-coding scheme and the corresponding pin numbers for each wire.

-

Straighten and Align: Straighten each wire and arrange them side by side in the order specified by the pinout diagram. Take care to align the wires neatly and avoid any crossovers or tangles.

-

Double-Check Alignment: Once the wires are arranged, double-check their alignment against the pinout diagram to ensure accuracy. Any mistakes at this stage could result in a faulty connection, so it’s essential to take your time and verify each wire’s position.

Inserting Wires into RJ45 Connector

With the cable prepared and the wires arranged correctly, it’s time to insert them into the RJ45 connector. Follow these steps to complete the crimping process:

-

Trim Excess Wires: Before inserting the wires into the connector, use wire cutters to trim any excess length, leaving just enough wire to reach the end of the connector.

-

Insert Wires: Carefully insert each wire into its corresponding slot within the RJ45 connector, ensuring that they are fully seated and making good contact with the metal pins inside the connector.

-

Verify Alignment: Once all the wires are inserted, double-check their alignment to ensure they match the pinout diagram. Any misalignment could result in a faulty connection, so it’s crucial to verify before proceeding.

-

Crimp the Connector: Finally, use a crimping tool to secure the connector onto the wires. Apply firm and even pressure to ensure a strong connection, then inspect the crimped connector to ensure it’s securely attached.

Following these step-by-step instructions will enable you to successfully crimp RJ45 sockets onto Ethernet cables, allowing you to create reliable network connections for your projects.

Common Mistakes to Avoid When Crimping RJ45 Sockets

Misalignment of Wires

One of the most common mistakes encountered when crimping RJ45 sockets is the misalignment of wires. This occurs when the individual wires within the Ethernet cable are not properly arranged or inserted into the RJ45 connector. Misalignment can lead to poor connectivity, signal loss, or even complete network failure.

To avoid this mistake, take care to align the wires according to the correct pinout configuration before inserting them into the connector. Double-check the alignment against a pinout diagram to ensure accuracy. Additionally, make sure each wire is fully seated within its corresponding slot in the connector to prevent any loose connections.

Over-crimping or Under-crimping

Another common pitfall when crimping RJ45 sockets is applying too much or too little pressure during the crimping process. Over-crimping occurs when excessive force is applied, causing the metal tabs inside the connector to deform or damage the wires. On the other hand, under-crimping results in a weak or incomplete connection, leading to intermittent connectivity issues or signal degradation.

To achieve the optimal crimp, use a crimping tool specifically designed for RJ45 connectors and apply firm but controlled pressure. Avoid squeezing the connector too tightly, as this can damage the wires or connector. Conversely, ensure that enough pressure is applied to securely fasten the connector onto the wires, providing a reliable connection.

Using Incorrect Pinout Configuration

Using an incorrect pinout configuration is perhaps one of the most critical mistakes to avoid when crimping RJ45 sockets. Each Ethernet cable follows a specific pinout standard, such as T568A or T568B, which determines the order in which wires are arranged within the connector. Using the wrong pinout configuration can result in crossed connections, signal interference, or network incompatibility.

Before crimping, always refer to the appropriate pinout diagram for your specific application and ensure that the wires are arranged accordingly. Pay close attention to the color-coding scheme and the corresponding pin numbers to avoid any errors. Verifying the pinout configuration before crimping can save time and prevent headaches later on.

By being mindful of these common mistakes and taking the necessary precautions, you can ensure a successful crimping process and create reliable RJ45 connections for your networking projects. Remember to double-check your work, use the right tools, and follow the correct procedures to achieve optimal results.

Testing the Crimped RJ45 Socket

Continuity Testing

Continuity testing is a crucial step in ensuring the integrity of a crimped RJ45 socket. It involves checking for a continuous electrical connection between the pins of the connector and the corresponding wires within the Ethernet cable. By verifying continuity, you can confirm that each wire is properly seated in its designated slot and that there are no breaks or faults in the connection.

To perform continuity testing, you’ll need a multimeter set to the continuity or resistance setting. Follow these steps:

-

Set Up the Multimeter: Turn on the multimeter and set it to the continuity or resistance setting, depending on the capabilities of your device.

-

Probe the Pins: Place one probe of the multimeter on one of the pins of the RJ45 connector and the other probe on the corresponding wire at the opposite end of the cable. Repeat this process for each pin and wire pair, checking for continuity between them.

-

Listen for the Beep: If continuity is present, the multimeter will emit a beep or display a low resistance reading, indicating a complete electrical connection. If no beep is heard or the reading is infinite, there may be a break or fault in the connection that requires further investigation.

-

Inspect for Visual Cues: In addition to using a multimeter, visually inspect the crimped connector for any signs of damage or poor connections. Look for loose wires, exposed conductors, or irregularities in the crimping process that could indicate a problem.

Ethernet Cable Tester Usage

Ethernet cable testers are specialized tools designed to quickly and accurately assess the connectivity of Ethernet cables, including those with RJ45 connectors. These testers typically consist of a main unit and remote unit connected by a length of cable, along with a display screen or indicator lights to provide feedback on the connection status.

To use an Ethernet cable tester:

-

Connect the Tester: Attach the main unit of the tester to one end of the Ethernet cable and the remote unit to the opposite end. Ensure that the connectors are securely seated and that the cable is properly inserted into both units.

-

Initiate Testing: Activate the tester and follow the prompts or instructions provided by the device. The tester will typically perform a series of tests to check for continuity, wiring errors, and signal integrity.

-

Interpret the Results: Once testing is complete, review the results displayed on the tester’s screen or indicated by the lights. A successful test will show that all wires are properly connected, with no faults or errors detected. If any issues are identified, refer to the tester’s documentation for troubleshooting guidance.

Verifying Connectivity

After performing continuity testing and using an Ethernet cable tester, it’s essential to verify the actual connectivity of the crimped RJ45 socket in a real-world scenario. This involves connecting the cable to network devices such as computers, routers, or switches and confirming that data can be transmitted and received without any issues.

To verify connectivity:

-

Connect the Cable: Plug one end of the crimped Ethernet cable into a network device, such as a computer or router, and the other end into a compatible port on a network switch or hub.

-

Check for Link Lights: Look for link lights or indicators on both the network device and the network switch to confirm that a physical connection has been established. These lights typically indicate the presence of a network connection and the speed of data transmission.

-

Test Data Transmission: Transfer data between connected devices to ensure that the network connection is functioning correctly. You can do this by accessing network resources, browsing the internet, or transferring files between devices.

By performing continuity testing, using an Ethernet cable tester, and verifying connectivity in a real-world scenario, you can ensure that your crimped RJ45 sockets are properly installed and capable of reliably transmitting data across your network infrastructure.

Troubleshooting Crimping Issues

Identifying Wiring Errors

Identifying wiring errors is a critical step in troubleshooting crimping issues with RJ45 sockets. Common wiring errors can include crossed wires, misaligned pins, or incorrect pinout configurations. These errors can lead to connectivity issues, signal interference, or even network failure.

To identify wiring errors, visually inspect the crimped RJ45 socket for any signs of irregularities. Look for loose wires, exposed conductors, or wires inserted into the wrong slots within the connector. Additionally, use a multimeter or cable tester to check for continuity between the pins of the connector and the corresponding wires within the Ethernet cable. Any discrepancies between the expected pinout configuration and the actual wiring arrangement indicate a potential wiring error that needs to be addressed.

Fixing Faulty Connections

Fixing faulty connections is essential for restoring proper functionality to crimped RJ45 sockets. Whether due to wiring errors, loose connections, or physical damage, addressing faulty connections requires careful attention to detail and proper troubleshooting techniques.

To fix faulty connections, follow these steps:

-

Identify the Issue: Determine the cause of the faulty connection by inspecting the crimped RJ45 socket and conducting continuity testing with a multimeter or cable tester.

-

Re-crimp the Connector: If the issue is due to a loose or improperly crimped connector, carefully remove the existing connector from the Ethernet cable and re-crimp a new connector onto the wires. Ensure that the wires are properly aligned and securely seated within the connector before crimping.

-

Repair Damaged Wires: If any wires are damaged or broken, trim away the damaged sections using wire cutters and strip the ends of the wires to expose fresh conductors. Reinsert the repaired wires into the appropriate slots within the RJ45 connector and crimp the connector as usual.

-

Verify Connectivity: Once the faulty connection has been addressed, use a cable tester or perform a real-world connectivity test to verify that the issue has been resolved. Ensure that data can be transmitted and received without any interruptions or errors.

Using Cable Tester for Diagnosis

A cable tester is a valuable tool for diagnosing crimping issues and identifying connectivity problems in RJ45 sockets. Cable testers are designed to quickly and accurately assess the continuity, wiring integrity, and signal strength of Ethernet cables, making them indispensable for troubleshooting network infrastructure.

To use a cable tester for diagnosis:

-

Connect the Tester: Attach the main unit of the cable tester to one end of the Ethernet cable and the remote unit to the opposite end. Ensure that the connectors are securely seated and that the cable is properly inserted into both units.

-

Initiate Testing: Activate the cable tester and follow the prompts or instructions provided by the device. The tester will perform a series of tests to check for continuity, wiring errors, and signal integrity.

-

Interpret the Results: Review the results displayed on the tester’s screen or indicated by the lights. A successful test will show that all wires are properly connected, with no faults or errors detected. If any issues are identified, refer to the tester’s documentation for troubleshooting guidance.

By following these troubleshooting steps and using a cable tester for diagnosis, you can effectively identify and address crimping issues with RJ45 sockets, ensuring reliable network connectivity for your projects.

Advanced Techniques and Tips for Crimping RJ45 Sockets

Shielded vs. Unshielded Cable Considerations

When crimping RJ45 sockets, it’s essential to consider whether you’re working with shielded or unshielded Ethernet cable. Shielded cable contains an additional layer of shielding, typically made of metal foil or braided wire, which helps protect the signal from electromagnetic interference (EMI) and radio frequency interference (RFI). Unshielded cable, on the other hand, lacks this additional layer of protection but is generally more flexible and cost-effective.

Tips for Crimping Shielded Cable:

- Use connectors specifically designed for shielded cable to ensure proper grounding and shielding effectiveness.

- Take care not to damage the shielding layer when stripping the cable jacket, as this can compromise the cable’s effectiveness.

- Ensure that the shielding is properly terminated and grounded to prevent signal leakage or interference.

Tips for Crimping Unshielded Cable:

- Use high-quality connectors and ensure proper termination to minimize signal loss and maintain signal integrity.

- Pay attention to bend radius and cable routing to prevent damage to the cable and maintain optimal performance.

- Test the cable after crimping to verify connectivity and signal quality.

Using Strain Relief Boots

Strain relief boots are small, flexible covers that can be added to the RJ45 connector after crimping to provide additional support and protection to the cable. These boots help prevent cable damage and prolong the lifespan of the connection by reducing strain on the cable where it enters the connector.

Benefits of Using Strain Relief Boots:

- Prevents cable kinking and bending at the point of connection, reducing the risk of signal degradation or connection failure.

- Provides added protection against dust, moisture, and other environmental contaminants that can compromise the integrity of the connection.

- Improves cable management and aesthetics by keeping cables organized and protected.

When using strain relief boots, ensure that they are compatible with the RJ45 connector and properly sized to fit snugly over the connector body. Slide the boot onto the cable before crimping the connector, then push it up against the connector body after crimping to secure it in place.

Customizing Cable Lengths for Specific Applications

In some situations, you may need to customize the length of Ethernet cables to suit specific applications or installation requirements. Whether you need a longer or shorter cable, customizing cable lengths allows you to tailor your network infrastructure to fit your needs precisely.

Tips for Customizing Cable Lengths:

- Use high-quality cable and connectors to maintain signal integrity and reliability.

- Measure and cut the cable carefully to avoid waste and ensure an accurate fit for your application.

- Use cable management techniques such as cable ties or clips to secure and organize cables neatly and prevent tangling or tripping hazards.

- Test the custom cable after crimping to verify connectivity and signal quality.

Customizing cable lengths can be particularly useful in scenarios where standard-length cables are not suitable, such as installations in tight spaces or long-distance runs. By mastering the art of custom cable lengths, you can optimize your network infrastructure for maximum efficiency and performance.